U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA- HRT-17-095 Date: September 2017 |

Publication Number: FHWA- HRT-17-095 Date: September 2017 |

For all LTPP test sections in SPS-1 through -7 and GPS-6, -7, and -9, the time-series pavement conditions, distresses, and some of the FWD data were downloaded and organized in spreadsheet format for analyses. The data from these LTPP test sections and a few pavement sections from the CDOT, LADOTD, and WSDOT databases were modeled using the proper mathematical function and were subjected to analyses. The procedures and the results of the analyses of the LTPP flexible pavement condition and distress data are presented in this chapter, while the procedure and results for rigid pavement condition and distress data are presented in chapter 6. Results of the analyses of the FWD data are presented and discussed in chapter 7. Finally, the results of the analyses of the CDOT, LADOTD, and WSDOT data are presented and discussed in chapter 9. The information in this chapter is arranged in the following sections:

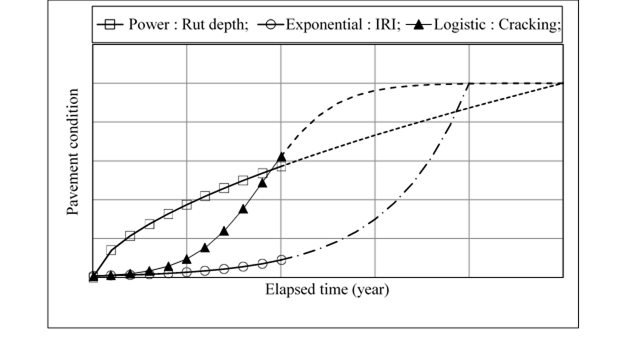

The time-series pavement condition and distress data of all test sections in the SPS-1 through -7 and GPS–6, -7, and -9 experiments were downloaded, organized, and modeled using the proper mathematical functions based on the type of pavement condition (IRI) or distress (rut depth, and cracking). The mathematical functions listed in table 27 and shown in figure 50 were selected based on reported trends and mechanisms of pavement deterioration.(37,81,78) For example, rutting typically occurs early in the asphalt pavement’s life, and its accumulation rate decreases over time as the pavement materials densify under traffic loads.

Table 27. Description of the mathematical functions used in the analyses of the pavement distress and condition data.

| Pavement Condition or Distress | Function Type |

|---|---|

| IRI (inches/mi (m/km)) | Exponential function |

| Rut depth (inches (mm)) | Power function |

| Cracking (length, area, or percent) | Logistic (S-shaped) |

Figure 50. Graph. Exponential, power, and logistic (S-shaped) curves.

Therefore, a power function is typically used to model the time-series rut depth data. On the other hand, pavement roughness usually increases exponentially as the pavement ages, deteriorates, and becomes uneven causing increases in the dynamic effects of traffic loads. Hence, an exponential function is typically used to model the pavement roughness (IRI). Finally, the propagation of pavement cracks usually follows three stages. In the first stage, a few cracks appear in the early pavement life; their number and length increase exponentially. In the second stage, the number and length of cracks increase almost linearly over time. In this stage, a few new cracks are initiated and most existing cracks approach their maximum possible lengths (lane width or the pavement section length). In the third stage, the number of cracks and their length reach equilibrium as shown by the logistic curve in figure 50. Given this scenario, the modeling of crack propagation over time could be achieved using two different functions, depending on the availability of the data. If the cracking data are available over a short period of time after construction (stage one data only), an exponential function could be used to model the data. On the other hand, if the cracking data are available when the pavement is old (stage three only), a power function could be used. The modeling of the crack propagation using the logistic function cannot be confidently achieved unless at least four data points are available spanning the three crack propagation stages. To reduce the effect of the problem and to increase the number of test sections included in the analyses, one crack saturation point was assumed for each type of cracking. The assumed crack saturation points used throughout this study are listed in table 28. The assumption of the crack saturation points was based on engineering logic. For example, the saturation point for alligator cracking is the entire surface area of the pavement section, whereas the saturation point for longitudinal cracking is three cracks along the entire pavement section length. Note that the square, circle, and triangle symbols in figure 50 represent measured data. The solid portions of the curves are fit to the measured data while the dashed portions are forecasted based on the mathematical function fitting the data. It should be noted that the three mathematical models fit the LTPP pavement condition and distress data for all test sections and State data.

Table 28. Crack saturation values used in the analyses of the pavement cracking data.

| Cracking Type | Saturation Value | Reason | ||

|---|---|---|---|---|

| Per 500 ft (152.4 m) LTPP Test Section |

Per 0.1km |

Per 0.1mi |

||

| Alligator cracking | 5,906 ft2 (549 m2) |

360 m2 | 6,336 ft2 | 100-percent of section cracked (12-ft (3.66-m) lane width) |

| Longitudinal cracking11,500 ft (457.2 m) | 1,500 ft (457.2 m) |

300 m | 1,584 ft | Three cracks along the entire section length |

| Transverse cracking (length), flexible pavements | 500ft (152.4 m) |

100 m | 528 ft | One crack every 12ft (3.65 m) |

| Number of transverse cracks, flexible pavements1 | 42 | 28 | 44 | One crack each 3.65 m (12ft) |

| Transverse cracking (length), rigid pavements | 375ft (114 m) |

75 m | 396 ft | One crack per slab (16-ft (4.87-m) joint spacing) |

| Number of transverse cracks, rigid pavements1 | 31 | 21 | 33 | One crack per slab (16-ft (4.87-m) joint spacing) |

| 1Data included for convenience. The analyses were conducted using the measured crack lengths and alligator cracked areas. | ||||

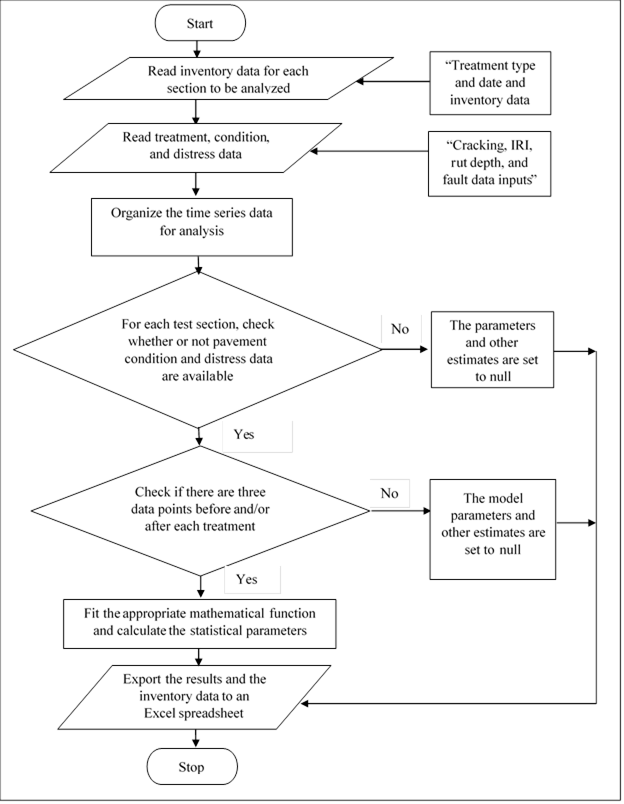

After selecting the proper mathematical function, the least squares regression technique was used to determine the statistical parameters of the selected mathematical functions. The least squares regression technique is based on minimizing the sum of the squared differences (error) between the calculated and the measured data.(3) To expedite the analyses, a MATLAB®-based computer program was written to complete the following functions for each pavement condition and distress dataset of each LTPP test section and for each pavement treatment type (see the program flowchart in figure 51):

Figure 51. Illustration. Flowchart of the MATLAB® program.

The MATLAB® output data were then subjected to further analyses to estimate the following parameters for each test section and for each treatment type:

Recall that the main objective of the SPS-1 experiment is to study the effects of the conditions in climatic regions and the following structural factors on pavement performance:(65)

The analyses of the impacts of the various variables were accomplished in the following steps:

The impacts of the conditions in the four climatic regions (WF, WNF, DF, and DNF), the AC thickness (4 and 7 inches (102 or 178 mm)), and drainable and undrainable bases on the pavement performance in terms of RFP and RSP were analyzed. The detailed results of the analyses (the calculated and rounded minimum, maximum, and average RFPs or RSPs for the SPS-1 test sections) were submitted to FHWA and are available from the LTPP Customer Support Services.(79) For convenience, the detailed results are summarized in table 29 through table 34.

The data in table 29 through table 34 address the impact of the climatic regions, the AC thickness, and drainable and undrainable bases on the pavement performance (in terms of RFPs and RSPs) of the SPS-1 test sections. The figures in the tables (which are rounded to whole numbers) indicate the differences in years in RFPs or RSPs of the SPS-1 test sections having the column heading parameters compared with RFPs and RSPs of the SPS-1 test sections having the row heading parameters. Thus, in table 29 through table 33, the diagonal indicated by asterisks represents the line of symmetry. If the table were folded along the diagonal, the aligned numbers from above and from below the diagonal would be the same but with different sign. The proper reading of the data in the tables is illustrated in the two examples following the tables.

Table 29. Summary of the results of analyses of the impacts of design factors on RFP of LTPP SPS-1 test sections based on IRI (years).

| Climatic Region, AC Thickness, and Drainage Subgroup |

Climatic Region, AC Thickness, and Drainage Subgroup | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | |||||||||||||||

| 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | |||||||||||

| D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | |||

| WF | 4-inch AC | D | * | –5 | 0 | –2 | 2 | 2 | 2 | 2 | 0 | 2 | 2 | 2 | 2 | 1 | 2 | 2 |

| ND | 5 | * | 4 | 3 | 7 | 7 | 7 | 7 | 5 | 7 | 7 | 7 | 7 | 6 | 7 | 7 | ||

| 7-inch AC | D | 0 | –4 | * | –1 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | |

| ND | 2 | –3 | 1 | * | 4 | 3 | 4 | 4 | 2 | 4 | 4 | 4 | 4 | 3 | 4 | 4 | ||

| WNF | 4-inch AC | D | –2 | –7 | –2 | –4 | * | 0 | 0 | 0 | –2 | 0 | 0 | 0 | 0 | –1 | 0 | 0 |

| ND | –2 | –7 | –2 | –3 | 0 | * | 0 | 0 | –1 | 0 | 0 | 0 | 0 | –1 | 0 | 0 | ||

| 7-inch AC | D | –2 | –7 | –2 | –4 | 0 | 0 | * | 0 | –2 | 0 | 0 | 0 | 0 | –1 | 0 | 0 | |

| ND | –2 | –7 | –2 | –4 | 0 | 0 | 0 | * | –2 | 0 | 0 | 0 | 0 | –1 | 0 | 0 | ||

| DF | 4-inch AC | D | 0 | –5 | –1 | –2 | 2 | 1 | 2 | 2 | * | 2 | 2 | 2 | 2 | 1 | 2 | 2 |

| ND | –2 | –7 | –2 | –4 | 0 | 0 | 0 | 0 | –2 | * | 0 | 0 | 0 | –1 | 0 | 0 | ||

| 7-inch AC | D | –2 | –7 | –2 | –4 | 0 | 0 | 0 | 0 | –2 | 0 | * | 0 | 0 | –1 | 0 | 0 | |

| ND | –2 | –7 | –2 | –4 | 0 | 0 | 0 | 0 | –2 | 0 | 0 | * | 0 | –1 | 0 | 0 | ||

| DNF | 4-inch AC | D | –2 | –7 | –2 | –4 | 0 | 0 | 0 | 0 | –2 | 0 | 0 | 0 | * | –1 | 0 | 0 |

| ND | –1 | –6 | –1 | –3 | 1 | 1 | 1 | 1 | –1 | 1 | 1 | 1 | 1 | * | 1 | 1 | ||

| 7-inch AC | D | –2 | –7 | –2 | –4 | 0 | 0 | 0 | 0 | –2 | 0 | 0 | 0 | 0 | –1 | * | 0 | |

| ND | –2 | –7 | –2 | –4 | 0 | 0 | 0 | 0 | –2 | 0 | 0 | 0 | 0 | –1 | 0 | * | ||

| * Indicates the line of symmetry along the diagonal of the table. 1 inch = 25.4 mm. D = Drainable base. ND = Undrainable base. |

||||||||||||||||||

Table 30. Summary of the results of analyses of the impacts of design factors on RFP/RSP of LTPP SPS-1 test sections based on rut depth (years).

| Climatic Region, AC Thickness, and Drainage Subgroup |

Climatic Region, AC Thickness, and Drainage Subgroup | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | |||||||||||||||

| 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | |||||||||||

| D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | |||

| WF | 4-inch AC | D | * | –5 | –1 | –3 | 5 | 5 | 5 | 5 | 4 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| ND | 5 | * | 4 | 2 | 10 | 10 | 10 | 10 | 9 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | ||

| 7-inch AC | D | 1 | –4 | * | –3 | 6 | 6 | 5 | 6 | 5 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |

| ND | 3 | –2 | 3 | * | 8 | 9 | 8 | 9 | 7 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | ||

| WNF | 4-inch AC | D | –5 | –10 | –6 | –8 | * | 0 | 0 | 1 | –1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| ND | –5 | –10 | –6 | –9 | 0 | * | 0 | 0 | –1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| 7-inch AC | D | –5 | –10 | –5 | –8 | 0 | 0 | * | 1 | –1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| ND | –5 | –10 | –6 | –9 | –1 | 0 | –1 | * | –2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| DF | 4-inch AC | D | –4 | –9 | –5 | –7 | 1 | 1 | 1 | 2 | * | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| ND | –6 | –11 | –7 | –9 | –1 | –1 | –1 | –1 | –2 | * | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 7-inch AC | D | –6 | –11 | –7 | –9 | –1 | –1 | –1 | –1 | –2 | 0 | * | 0 | 0 | 0 | 0 | 0 | |

| ND | –6 | –11 | –7 | –9 | –1 | –1 | –1 | –1 | –2 | 0 | 0 | * | 0 | 0 | 0 | 0 | ||

| DNF | 4-inch AC | D | –6 | –11 | –7 | –9 | –1 | –1 | –1 | –1 | –2 | 0 | 0 | 0 | * | 0 | 0 | 0 |

| ND | –6 | –11 | –7 | –9 | –1 | –1 | –1 | –1 | –2 | 0 | 0 | 0 | 0 | * | 0 | 0 | ||

| 7-inch AC | D | –6 | –11 | –7 | –9 | –1 | –1 | –1 | –1 | –2 | 0 | 0 | 0 | 0 | 0 | * | 0 | |

| ND | –6 | –11 | –7 | –9 | –1 | –1 | –1 | –1 | –2 | 0 | 0 | 0 | 0 | 0 | 0 | * | ||

| * Indicates the line of symmetry along the diagonal of the table. 1 inch = 25.4 mm. D = Drainable base. ND = Undrainable base. |

||||||||||||||||||

Table 31. Summary of the results of analyses of the impacts of design factors on RSP of LTPP SPS-1 test sections based on alligator cracking (years).

| Climatic Region, AC Thickness, and Drainage Subgroup |

Climatic Region, AC Thickness, and Drainage Subgroup | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | |||||||||||||||

| 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | |||||||||||

| D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | |||

| WF | 4-inch AC | D | * | –4 | –3 | –3 | 0 | 0 | 2 | 2 | –3 | –5 | –2 | –3 | –5 | –6 | –1 | –2 |

| ND | 4 | * | 1 | 1 | 4 | 3 | 5 | 5 | 0 | –2 | 2 | 1 | –1 | –2 | 3 | 2 | ||

| 7-inch AC | D | 3 | –1 | * | 0 | 3 | 2 | 4 | 4 | –1 | –3 | 1 | 0 | –2 | –3 | 2 | 1 | |

| ND | 3 | –1 | 0 | * | 3 | 3 | 5 | 5 | 0 | –2 | 1 | 0 | –1 | –3 | 2 | 2 | ||

| WNF | 4-inch AC | D | 0 | –4 | –3 | –3 | * | –1 | 1 | 1 | –4 | –6 | –2 | –3 | –5 | –6 | –1 | –2 |

| ND | 0 | –3 | –2 | –3 | 1 | * | 2 | 2 | –3 | –5 | –2 | –3 | –4 | –6 | –1 | –1 | ||

| 7-inch AC | D | –2 | –5 | –4 | –5 | –1 | –2 | * | 0 | –5 | –7 | –4 | –5 | –6 | –8 | –3 | –3 | |

| ND | –2 | –5 | –4 | –5 | –1 | –2 | 0 | * | –5 | –7 | –4 | –4 | –6 | –8 | –3 | –3 | ||

| DF | 4-inch AC | D | 3 | 0 | 1 | 0 | 4 | 3 | 5 | 5 | * | –2 | 1 | 1 | –1 | –3 | 2 | 2 |

| ND | 5 | 2 | 3 | 2 | 6 | 5 | 7 | 7 | 2 | * | 3 | 2 | 1 | –1 | 4 | 4 | ||

| 7-inch AC | D | 2 | –2 | –1 | –1 | 2 | 2 | 4 | 4 | –1 | –3 | * | –1 | –2 | –4 | 1 | 0 | |

| ND | 3 | –1 | 0 | 0 | 3 | 3 | 5 | 4 | –1 | –2 | 1 | * | –2 | –3 | 2 | 1 | ||

| DNF | 4-inch AC | D | 5 | 1 | 2 | 1 | 5 | 4 | 6 | 6 | 1 | –1 | 2 | 2 | * | –1 | 3 | 3 |

| ND | 6 | 2 | 3 | 3 | 6 | 6 | 8 | 8 | 3 | 1 | 4 | 3 | 1 | * | 5 | 4 | ||

| 7-inch AC | D | 1 | –3 | –2 | –2 | 1 | 1 | 3 | 3 | –2 | –4 | –1 | –2 | –3 | –5 | * | 0 | |

| ND | 2 | –2 | –1 | –2 | 2 | 1 | 3 | 3 | –2 | –4 | 0 | –1 | –3 | –4 | 0 | * | ||

| * Indicates the line of symmetry along the diagonal of the table. 1 inch = 25.4 mm. D = Drainable base. ND = Undrainable base. |

||||||||||||||||||

Table 32. Summary of the results of analyses of the impacts of design factors on RSP of LTPP SPS-1 test sections based on longitudinal cracking (years).

| Climatic Region, AC Thickness, and Drainage Subgroup |

Climatic Region, AC Thickness, and Drainage Subgroup | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | |||||||||||||||

| 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | |||||||||||

| D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | |||

| WF | 4-inch AC |

D | * | –1 | –1 | 0 | 5 | 6 | 6 | 5 | 1 | 0 | –1 | 0 | 6 | 5 | 6 | 7 |

| ND | 1 | * | 0 | 1 | 6 | 7 | 7 | 6 | 1 | 1 | 0 | 1 | 7 | 6 | 6 | 8 | ||

| 7-inch AC |

D | 1 | 0 | * | 1 | 6 | 7 | 7 | 6 | 2 | 1 | 0 | 1 | 7 | 6 | 7 | 8 | |

| ND | 0 | –1 | –1 | * | 5 | 6 | 6 | 5 | 0 | 0 | –1 | 0 | 6 | 5 | 5 | 7 | ||

| WNF | 4-inch AC |

D | –5 | –6 | –6 | –5 | * | 1 | 1 | 0 | –5 | –5 | –6 | –5 | 1 | 0 | 0 | 2 |

| ND | –6 | –7 | –7 | –6 | –1 | * | 0 | –2 | –6 | –6 | –7 | –6 | –1 | –1 | –1 | 1 | ||

| 7-inch AC |

D | –6 | –7 | –7 | –6 | –1 | 0 | * | –1 | –6 | –6 | –7 | –6 | 0 | –1 | –1 | 1 | |

| ND | –5 | –6 | –6 | –5 | 0 | 2 | 1 | * | –4 | –5 | –5 | –5 | 1 | 0 | 1 | 2 | ||

| DF | 4-inch AC |

D | –1 | –1 | –2 | 0 | 5 | 6 | 6 | 4 | * | 0 | –1 | –1 | 5 | 4 | 5 | 7 |

| ND | 0 | –1 | –1 | 0 | 5 | 6 | 6 | 5 | 0 | * | –1 | 0 | 6 | 5 | 5 | 7 | ||

| 7-inch AC |

D | 1 | 0 | 0 | 1 | 6 | 7 | 7 | 5 | 1 | 1 | * | 1 | 7 | 6 | 6 | 8 | |

| ND | 0 | –1 | –1 | 0 | 5 | 6 | 6 | 5 | 1 | 0 | –1 | * | 6 | 5 | 6 | 7 | ||

| DNF | 4-inch AC |

D | –6 | –7 | –7 | –6 | –1 | 1 | 0 | –1 | –5 | –6 | –7 | –6 | * | –1 | 0 | 1 |

| ND | –5 | –6 | –6 | –5 | 0 | 1 | 1 | 0 | –4 | –5 | –6 | –5 | 1 | * | 1 | 2 | ||

| 7-inch AC |

D | –6 | –6 | –7 | –5 | 0 | 1 | 1 | –1 | –5 | –5 | –6 | –6 | 0 | –1 | * | 2 | |

| ND | –7 | –8 | –8 | –7 | –2 | –1 | –1 | –2 | –7 | –7 | –8 | –7 | –1 | –2 | –2 | * | ||

| * Indicates the line of symmetry along the diagonal of the table. 1 inch = 25.4 mm. D = Drainable base. ND = Undrainable base. |

||||||||||||||||||

Table 33. Summary of the results of analyses of the impacts of design factors on RSP of LTPP SPS-1 test sections based on transverse cracking (years).

| Climatic Region, AC Thickness, and Drainage Subgroup |

Climatic Region, AC Thickness, and Drainage Subgroup | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | |||||||||||||||

| 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | 4-inch AC | 7-inch AC | |||||||||||

| D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | D | ND | |||

| WF | 4-inch AC | D | * | 1 | 2 | 1 | 3 | 3 | 4 | 3 | –3 | 2 | –3 | 0 | –1 | 2 | 2 | 0 |

| ND | –1 | * | 2 | 1 | 2 | 2 | 3 | 2 | –4 | 1 | –4 | 0 | –1 | 1 | 1 | 0 | ||

| 7-inch AC | D | –2 | –2 | * | –1 | 1 | 0 | 1 | 1 | –6 | 0 | –5 | –2 | –3 | –1 | 0 | –2 | |

| ND | –1 | –1 | 1 | * | 2 | 1 | 2 | 2 | –5 | 1 | –4 | –1 | –2 | 0 | 1 | –1 | ||

| WNF | 4-inch AC | D | –3 | –2 | –1 | –2 | * | –1 | 0 | 0 | –7 | –1 | –6 | –3 | –4 | –1 | –1 | –3 |

| ND | –3 | –2 | 0 | –1 | 1 | * | 1 | 1 | –6 | 0 | –5 | –2 | –3 | –1 | 0 | –2 | ||

| 7-inch AC | D | –4 | –3 | –1 | –2 | 0 | –1 | * | 0 | –7 | –1 | –6 | –3 | –4 | –2 | –1 | –3 | |

| ND | –3 | –2 | –1 | –2 | 0 | –1 | 0 | * | –7 | –1 | –6 | –3 | –4 | –1 | –1 | –3 | ||

| DF | 4-inch AC | D | 3 | 4 | 6 | 5 | 7 | 6 | 7 | 7 | * | 6 | 1 | 4 | 3 | 5 | 6 | 4 |

| ND | –2 | –1 | 0 | –1 | 1 | 0 | 1 | 1 | –6 | * | –5 | –2 | –3 | 0 | 0 | –2 | ||

| 7-inch AC | D | 3 | 4 | 5 | 4 | 6 | 5 | 6 | 6 | –1 | 5 | * | 3 | 2 | 5 | 5 | 3 | |

| ND | 0 | 0 | 2 | 1 | 3 | 2 | 3 | 3 | –4 | 2 | –3 | * | –1 | 1 | 2 | 0 | ||

| DNF | 4-inch AC | D | 1 | 1 | 3 | 2 | 4 | 3 | 4 | 4 | –3 | 3 | –2 | 1 | * | 2 | 3 | 1 |

| ND | –2 | –1 | 1 | 0 | 1 | 1 | 2 | 1 | –5 | 0 | –5 | –1 | –2 | * | 0 | –1 | ||

| 7-inch AC | D | –2 | –1 | 0 | –1 | 1 | 0 | 1 | 1 | –6 | 0 | –5 | –2 | –3 | 0 | * | –2 | |

| ND | 0 | 0 | 2 | 1 | 3 | 2 | 3 | 3 | –4 | 2 | –3 | 0 | –1 | 1 | 2 | * | ||

| * Indicates the line of symmetry along the diagonal of the table. 1 inch = 25.4 mm. D = Drainable base. ND = Undrainable base. |

||||||||||||||||||

Table 34. Summary of the results of analyses of the effects of climatic regions on the performance of the LTPP SPS-1 test sections.

| Condition or Distress Type | Climatic Region | Climatic Regions and the Percent of Test Sections Where RFP/RSP Was Better, Equal, or Worse Than Other Climatic Regions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | ||||||||||

| Better | Same | Worse | Better | Same | Worse | Better | Same | Worse | Better | Same | Worse | ||

| IRI | WF | — | — | — | 58 | 4 | 38 | 56 | 28 | 17 | 58 | 42 | 0 |

| WNF | 38 | 4 | 58 | — | — | — | 77 | 6 | 17 | 8 | 84 | 8 | |

| DF | 17 | 28 | 56 | 17 | 6 | 77 | — | — | — | 17 | 72 | 11 | |

| DNF | 0 | 42 | 58 | 8 | 84 | 8 | 11 | 72 | 17 | — | — | — | |

| Rut depth | WF | — | — | — | 83 | 17 | 0 | 82 | 13 | 5 | 73 | 27 | 0 |

| WNF | 0 | 17 | 83 | — | — | — | 23 | 68 | 9 | 9 | 91 | 0 | |

| DF | 5 | 13 | 82 | 9 | 68 | 23 | — | — | — | 0 | 100 | 0 | |

| DNF | 0 | 27 | 73 | 0 | 91 | 9 | 0 | 100 | 0 | — | — | — | |

| Alligator cracking | WF | — | — | — | 67 | 8 | 25 | 42 | 4 | 54 | 42 | 8 | 50 |

| WNF | 25 | 8 | 67 | — | — | — | 38 | 8 | 54 | 13 | 0 | 87 | |

| DF | 54 | 4 | 42 | 54 | 8 | 38 | — | — | — | 46 | 17 | 38 | |

| DNF | 50 | 8 | 42 | 87 | 0 | 13 | 38 | 17 | 46 | — | — | — | |

| Longitudinal cracking | WF | — | — | — | 88 | 8 | 4 | 46 | 4 | 50 | 92 | 8 | 0 |

| WNF | 4 | 8 | 88 | — | — | — | 8 | 29 | 63 | 42 | 42 | 16 | |

| DF | 50 | 4 | 46 | 63 | 29 | 8 | — | — | — | 67 | 29 | 4 | |

| DNF | 0 | 8 | 92 | 16 | 42 | 42 | 4 | 29 | 67 | — | — | — | |

| Transverse cracking | WF | — | — | — | 54 | 33 | 13 | 42 | 12 | 46 | 46 | 21 | 33 |

| WNF | 13 | 33 | 54 | — | — | — | 38 | 54 | 8 | 7 | 50 | 42 | |

| DF | 46 | 12 | 42 | 8 | 54 | 38 | — | — | — | 42 | 46 | 12 | |

| DNF | 33 | 21 | 46 | 42 | 50 | 7 | 12 | 46 | 42 | — | — | — | |

| — Indicates no data. | |||||||||||||

Consistent with this explanation of table 29 through table 33 and table 34, in the following subsections, the discussion of the results shown in those tables is organized according to the pavement condition and distress.

The average calculated RFPs listed in table 29 indicate that the differences between the average RFP of test sections located in different climatic regions and that have 4- or 7-inch (102- or 178‑mm)-thick AC layers with drainable and undrainable bases varied from –1 to 7 years. Because the 1-year difference was not significant and was within the data variability, it was considered a value of zero in the following discussion. Nevertheless, the data in table 29 indicate the following:

The impact of the climatic regions on pavement performance in terms of IRI is summarized in table 34. The data in the table indicate the following:

There are several significant initial conclusions regarding pavement performance that could be drawn from the findings listed in table 29 and table 34. However, these conclusions would be based on pavement roughness only. To make these conclusions a part of the global pavement performance, the research team decided to include them in the summary, conclusions, and recommendations section that follows the discussion of all the other distress types.

The average calculated RFPs or RSPs listed in table 30 indicate the following:

The impact of the climatic regions on pavement performance in terms of rut depth is summarized in table 34. The data in the table indicate the following:

The conclusions are included in the summary, conclusions, and recommendations section following the discussion of the other distress types.

The average calculated RSPs listed in table 31 indicate the following, on average:

The impact of the climatic regions on pavement performance in terms of alligator cracking is summarized in table 34. The data in the table indicate the following:

The conclusions are included in the summary, conclusions, and recommendations section following the discussion of the other distress types.

The average calculated RSPs listed in table 32 indicate the following, on average:

The impact of the climatic regions on pavement performance in terms of longitudinal cracking is summarized in table 34. The data in the table indicate the following:

Once again, the conclusions are included in the summary and conclusions section following the discussion of the other distress types.

The average calculated RSPs listed in table 33 indicate the following:

The impact of the climatic regions on pavement performance in terms of transverse cracking is summarized in table 34. The data in the table indicate the following:

The performance of each SPS-1 test section was analyzed using the available time-series IRI; rut depth; alligator, longitudinal, and transverse cracking data; and the proper mathematical functions. The results of the analyses were then expressed in terms of RFP for IRI, RFP/RSP for rut depth, and RSP for each cracking type. The test sections and their performance (RFP and RSP) were then tabulated using the SHRP IDs, climatic regions, AC thicknesses, and drainable or undrainable bases. Based on the results, the following conclusions were drawn:

The main objective of SPS-3 experiment was to compare the performance of different maintenance treatments on flexible pavements compared with the control (untreated) test sections. The 81SPS-3 test sites were initiated between 1990 and 1991 and were distributed across the United States and Canada. Each of the SPS-3 test sites consisted of 4 test sections for a total of 324 test sections. Fifty-one of the 81 test sites had control sections labeled 340. Each of the other 30sites were linked to a GPS test section (listed in table 35 along with their SHRP ID), which could be used as control sections.(60)

Table 35. Linked GPS sections that serve as control sections.(60)

| Site ID | Linked GPS Section ID |

|---|---|

| 04_A300 | 4_1036 |

| 04_B300 | 4_1021 |

| 04_D300 | 4_1016 |

| 05_A300 | 5_3071 |

| 08_B300 | 8_2008 |

| 12_A300 | 12_9054 |

| 12_B300 | 12_3997 |

| 12_C300 | 12_4154 |

| 16_A300 | 16_1020 |

| 16_B300 | 16_1021 |

| 16_C300 | 16_1010 |

| 28_A300 | 28_1802 |

| 30_A300 | 30_1001 |

| 32_A300 | 32_1021 |

| 32_C300 | 32_2027 |

| 40_B300 | 40_1015 |

| 40_C300 | 40_4088 |

| 47_A300 | 47_3101 |

| 47_B300 | 47_3075 |

| 47_C300 | 47_1023 |

| 48_D300 | 48_2172 |

| 48_G300 | 48_1169 |

| 49_A300 | 49_1004 |

| 49_B300 | 49_1017 |

| 49_C300 | 49_1006 |

| 53_A300 | 53_1008 |

| 53_B300 | 53_1501 |

| 53_C300 | 53_1801 |

| 56_A300 | 56_1007 |

| 56_B300 | 56_7775 |

Each of the four SPS-3 test sections in each test site was subjected to one of the following treatments (note that the numbers in parentheses are the LTPP designation of the treatment; for example, the designation of the joint and crack sealing is 410):

Several variables affect the performance of the treated pavement sections. These include climatic region, traffic, subgrade type, and the before treatment pavement condition and distress. Unfortunately, these variables could be separated to analyze the effects of each on pavement performance. The reason is that separating the variables yields statistically insignificant numbers of test sections to be used in the analyses.

To illustrate, table 36 lists the number of test sections that were available for analyses based on separation of the following variables:

Table 36. Number of test sections that have before treatment and after treatment pavement condition, distress, and traffic data.

| Condition or Distress Type | Treatment Type | Number of Test Sections by Climatic Region and Traffic Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | ||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | ||

| IRI | Thin overlay | 8 | 4 | 4 | 8 | 2 | 6 | 3 | 4 | 3 | 1 | 0 | 1 |

| Slurry seal | 6 | 4 | 4 | 6 | 3 | 6 | 3 | 3 | 2 | 1 | 0 | 1 | |

| Crack seal | 7 | 4 | 4 | 2 | 1 | 6 | 3 | 3 | 2 | 1 | 0 | 1 | |

| Aggregate seal coat | 5 | 4 | 4 | 7 | 2 | 5 | 3 | 3 | 3 | 0 | 1 | 1 | |

| Rut depth | Thin overlay | 4 | 2 | 2 | 4 | 2 | 7 | 2 | 1 | 2 | 0 | 0 | 1 |

| Slurry seal | 4 | 1 | 2 | 4 | 2 | 8 | 2 | 2 | 2 | 1 | 0 | 1 | |

| Crack seal | 4 | 1 | 3 | 2 | 0 | 6 | 3 | 2 | 2 | 0 | 0 | 1 | |

| Aggregate seal coat | 1 | 2 | 1 | 5 | 1 | 9 | 2 | 2 | 1 | 0 | 0 | 1 | |

| Alligator cracking | Thin overlay | 4 | 2 | 4 | 4 | 2 | 5 | 1 | 0 | 0 | 0 | 0 | 0 |

| Slurry seal | 1 | 0 | 3 | 5 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Crack seal | 1 | 0 | 1 | 3 | 2 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Aggregate seal coat | 2 | 0 | 3 | 4 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | Thin overlay | 4 | 2 | 4 | 4 | 2 | 5 | 1 | 0 | 0 | 0 | 0 | 0 |

| Slurry seal | 2 | 0 | 3 | 5 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Crack seal | 1 | 0 | 3 | 2 | 3 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Aggregate seal coat | 3 | 0 | 3 | 4 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Thin overlay | 4 | 2 | 4 | 4 | 2 | 5 | 1 | 0 | 0 | 0 | 0 | 0 |

| Slurry seal | 1 | 0 | 3 | 5 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Crack seal | 2 | 0 | 3 | 3 | 2 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Aggregate seal coat | 2 | 0 | 3 | 4 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Note: For each pavement condition and distress type, the test section was analyzed if the database contained at least one data point before treatment and/or three or more data points after treatment that could be modeled. L = low traffic (0 to 60,000 yearly ESAL). M = medium traffic (61,000 to 120,000 yearly ESAL). H = high traffic (> 120,000 yearly ESAL). |

|||||||||||||

It can be seen from the table that in some cells, especially in the DF and DNF regions and for some pavement distress types, the number of available test sections for analyses was not significant (ranges from 0 to 2). Therefore, the analyses were conducted to assess the impact of each treatment type in each climatic region and for each pavement condition and distress type. That is, the data were not separated based on traffic level, type of base and subbase, or type of roadbed.

Nevertheless, the analyses of the impacts of each of the four treatment types on pavement performance were accomplished using the following steps:

Results of the analyses are discussed per pavement condition and distress type in the next five subsections.

Listed in table 37 are the calculated minimum, maximum, and average RFPs based on IRI data for the SPS-3 test sections that were subjected to the same treatment type and located in the same climatic region. The table also includes the same data for the associated control sections. To assist the reader in interpreting the data, the numbers listed in the first row of the table, for example, indicate the following:

Table 37. Impacts of various maintenance treatments and control section on pavement performance in terms of RFP based on IRI.

| Climatic Region | Treatment Type | Remaining Functional Period (Years) | Difference in RFP (Years) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Sections | Control Sections | |||||||||

| Number of Sections | Min | Max | Average | Number of Sections | Min | Max | Average | |||

| WF | Thin overlay | 19 | 4 | 20 | 16 | 21 | 0 | 19 | 11 | 5 |

| WNF | 23 | 8 | 20 | 18 | 29 | 3 | 19 | 14 | 4 | |

| DF | 13 | 5 | 20 | 17 | 13 | 2 | 19 | 12 | 5 | |

| DNF | 3 | 3 | 13 | 9 | 4 | 3 | 18 | 11 | –2 | |

| WF | Slurry seal | 15 | 0 | 20 | 12 | 21 | 0 | 19 | 11 | 1 |

| WNF | 22 | 4 | 20 | 19 | 29 | 3 | 19 | 15 | 4 | |

| DF | 13 | 4 | 20 | 14 | 13 | 2 | 19 | 13 | 1 | |

| DNF | 2 | 9 | 20 | 15 | 4 | 3 | 18 | 11 | 4 | |

| WF | Crack seal | 18 | 0 | 20 | 11 | 21 | 0 | 19 | 11 | 0 |

| WNF | 12 | 1 | 20 | 16 | 29 | 3 | 19 | 14 | 2 | |

| DF | 13 | 3 | 20 | 15 | 13 | 2 | 18 | 12 | 3 | |

| DNF | 4 | 6 | 20 | 14 | 4 | 3 | 18 | 11 | 3 | |

| WF | Aggregate seal coat | 16 | 0 | 20 | 13 | 21 | 0 | 19 | 11 | 2 |

| WNF | 21 | 14 | 20 | 19 | 29 | 3 | 19 | 15 | 4 | |

| DF | 13 | 1 | 20 | 14 | 13 | 2 | 19 | 13 | 1 | |

| DNF | 3 | 4 | 10 | 7 | 4 | 3 | 18 | 11 | 4 | |

| Max = Maximum. Min = Minimum. |

||||||||||

Examination of the results of the analyses listed in table 37 indicates the following:

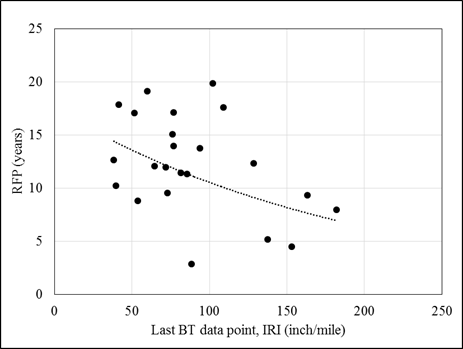

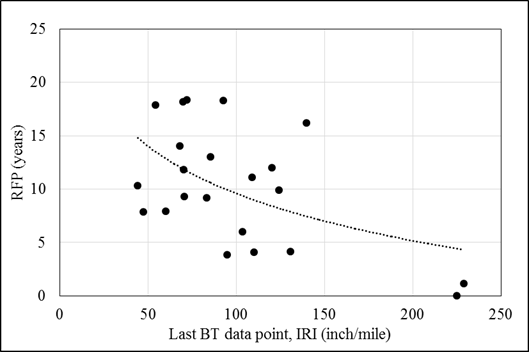

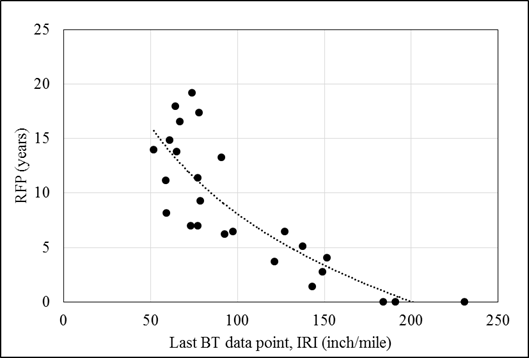

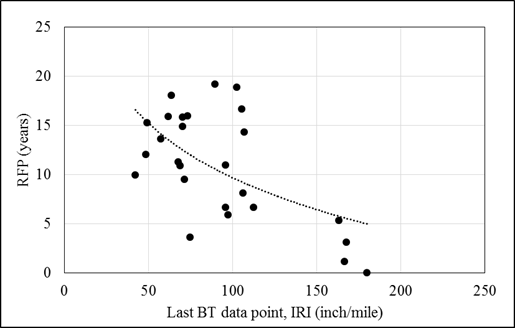

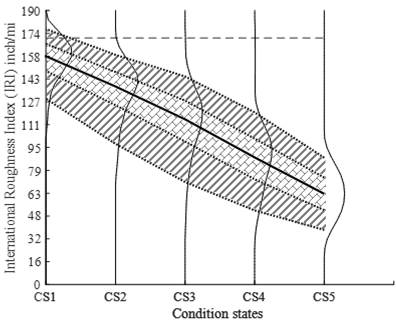

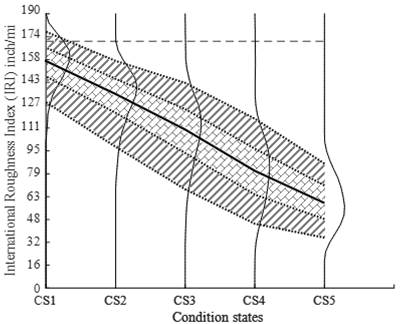

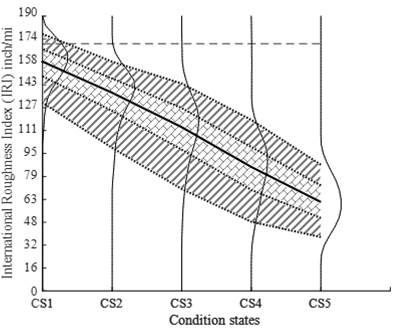

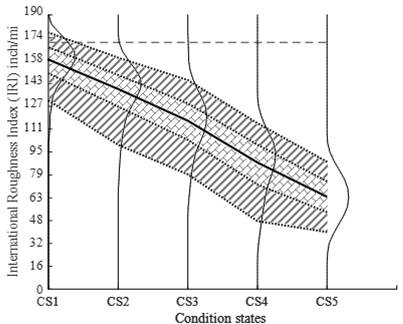

For some of the SPS-3 test sections, the LTPP database contained one or more IRI data points before the sections were subjected to maintenance treatments. To assess the impact of the before treatment pavement conditions on the after treatment pavement performance, for each maintenance treatment type, RFPs after treatment were plotted against the last collected IRI data point before treatment. The results are shown in figure 52 through figure 55 for thin overlay, slurry seal, crack seal, and aggregate seal coat, respectively. Although the data in the figures are widely scattered, the general trend is that the higher the IRI is before treatment, the lower the RFP is after treatment. This finding was expected and supports the notion that maintaining pavement sections in good conditions pays higher dividends than treating deteriorated sections. Nevertheless, the scattering of the data in figure 52 through figure 55 was likely caused by differences in the original pavement cross sections, pavement materials, roadbed soil, climatic region, and traffic level. Unfortunately, the number of test sections subjected to the same traffic level bracket was so small that no decision regarding the impacts of traffic could be made with any level of certainty. Note the solid best fit curves in figure 52 through figure 55 are not intended to model the data. They show only the global trend, and therefore the inclusion of statistics such as standard error would be meaningless. As stated previously, the data in the figures are a function of many other variables that were not included in the analyses. Because separation of variables yielded data for few test sections (two or fewer), no decision could be made with any degree of certainty.

1 inch/mi = 0.0158 m/km.

Figure 52. Graph. After-treatment RFP versus before-treatment IRI of LTPP SPS-3 test sections subjected to thin overlay.

1 inch/mi = 0.0158 m/km.

Figure 53. Graph. After-treatment RFP versus before-treatment IRI of LTPP SPS-3 test sections subjected to slurry seal.

1 inch/mi = 0.0158 m/km.

Figure 54. Graph. After-treatment RFP versus before-treatment IRI of LTPP SPS-3 test sections subjected to crack seal.

1 inch/mi = 0.0158 m/km.

Figure 55. Graph. After-treatment RFP versus before-treatment IRI of LTPP SPS-3 test sections subjected to aggregate seal coat.

Listed in table 38 are the calculated minimum, maximum, and average RFPs/RSPs based on rut depth data for the SPS-3 test sections that were subjected to the same treatment type and located in the same climatic region. The table also includes the same data for the associated control sections. The following summarizes the results:

Similar to the IRI analyses, RSPs after treatment were plotted against the last measured rut depth data point before treatment. The results were submitted to FHWA and are available from the LTPP Customer Support Services.(79) The data indicate that deeper before treatment rut depths led to lower after treatment RFP/RSP or better performance in terms of rut depth after treatment. The scattering of data in the figures is mainly due to differences in the original pavement cross sections, pavement materials, roadbed soil, climatic region, and traffic level.

Table 38. Impacts of various maintenance treatments and control section on pavement performance in terms of RFP/RSP based on rut depth.

| Climatic Region | Treatment Type | Remaining Functional/Structural Period (Years) | Difference in RFP/RSP (Years) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Sections | Control Sections | |||||||||

| Number of Sections | Min | Max | Average | Number of Sections | Min | Max | Average | |||

| WF | Thin overlay | 18 | 13 | 20 | 19 | 14 | 0 | 18 | 12 | 7 |

| WNF | 21 | 5 | 20 | 19 | 16 | 0 | 19 | 11 | 8 | |

| DF | 8 | 9 | 20 | 19 | 8 | 0 | 19 | 12 | 7 | |

| DNF | 4 | 0 | 20 | 10 | 3 | 0 | 16 | 11 | –1 | |

| WF | Slurry seal | 12 | 1 | 20 | 14 | 14 | 0 | 18 | 12 | 2 |

| WNF | 19 | 0 | 20 | 16 | 16 | 0 | 19 | 11 | 5 | |

| DF | 10 | 1 | 20 | 16 | 8 | 0 | 19 | 12 | 4 | |

| DNF | 3 | 1 | 20 | 14 | 3 | 0 | 16 | 11 | 3 | |

| WF | Crack seal | 11 | 0 | 20 | 13 | 14 | 0 | 18 | 12 | 1 |

| WNF | 9 | 0 | 20 | 16 | 16 | 0 | 19 | 11 | 5 | |

| DF | 9 | 2 | 20 | 18 | 8 | 0 | 18 | 11 | 7 | |

| DNF | 3 | 0 | 20 | 13 | 3 | 0 | 16 | 11 | 2 | |

| WF | Aggregate seal coat | 11 | 0 | 20 | 15 | 14 | 0 | 18 | 12 | 3 |

| WNF | 22 | 0 | 20 | 14 | 16 | 0 | 19 | 11 | 3 | |

| DF | 8 | 0 | 20 | 17 | 8 | 0 | 19 | 12 | 5 | |

| DNF | 2 | 0 | 20 | 20 | 3 | 0 | 16 | 11 | 9 | |

| Max = Maximum. Min = Minimum. |

||||||||||

Listed in table 39 are the calculated minimum, maximum, and average RSPs based on alligator cracking for the SPS-3 test sections and located in the same climatic region. The table also includes the same data for the associated control sections. The results listed in the table indicate the following:

Similar to the IRI and rut depths, for each treatment type, the RSPs of the test sections after treatment were plotted against the last collected alligator cracking data points before treatment. The results were submitted to FHWA and are available from the LTPP Customer Support Services.(79) In summary, the data indicate that as the alligator cracking increased, the after treatment RSPs decreased. That is, the data indicate that, on average, treating pavement sections at an early stage paid higher dividends than delayed treatment.

Table 39. Impacts of various maintenance treatments and control section on pavement performance in terms of RSP based on alligator cracking.

| Climatic Region | Treatment Type | Remaining Structural Period (Years) | Difference in RSP (Years) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Sections | Control Sections | |||||||||

| Number of Sections | Min | Max | Average | Number of Sections | Min | Max | Average | |||

| WF | Thin overlay | 21 | 2 | 20 | 10 | 15 | 0 | 16 | 8 | 2 |

| WNF | 24 | 3 | 20 | 11 | 20 | 0 | 17 | 9 | 2 | |

| DF | 11 | 4 | 20 | 11 | 8 | 6 | 18 | 12 | –1 | |

| DNF | 3 | 0 | 15 | 7 | 1 | 16 | 16 | 16 | –9 | |

| WF | Slurry seal | 16 | 0 | 20 | 7 | 15 | 0 | 16 | 8 | –1 |

| WNF | 30 | 2 | 20 | 10 | 20 | 0 | 17 | 10 | 0 | |

| DF | 10 | 3 | 20 | 9 | 8 | 6 | 18 | 12 | –3 | |

| DNF | 2 | 0 | 18 | 9 | 1 | 16 | 16 | 16 | –7 | |

| WF | Crack seal | 10 | 0 | 20 | 6 | 15 | 0 | 16 | 8 | –2 |

| WNF | 22 | 0 | 20 | 8 | 20 | 0 | 17 | 9 | –1 | |

| DF | 11 | 0 | 20 | 13 | 8 | 5 | 18 | 12 | 1 | |

| DNF | 2 | 0 | 2 | 1 | 1 | 16 | 16 | 16 | –15 | |

| WF | Aggregate seal coat | 15 | 2 | 20 | 10 | 15 | 0 | 16 | 8 | 2 |

| WNF | 18 | 4 | 20 | 12 | 20 | 0 | 17 | 10 | 2 | |

| DF | 9 | 6 | 20 | 11 | 8 | 6 | 18 | 12 | –1 | |

| DNF | 2 | 13 | 20 | 17 | 1 | 16 | 16 | 16 | 1 | |

| Max = Maximum. Min = Minimum. |

||||||||||

Listed in table 40 are the calculated minimum, maximum, and average RSPs based on longitudinal cracking for the SPS-3 test sections that were subjected to the same treatment type and located in the same climatic region. The table also includes the same data for the associated control sections. The results listed in the table indicate the following:

Once again, for each treatment type, the RSPs of the test sections after treatment were plotted against the last measured longitudinal cracking data point before treatment were submitted to FHWA and are available from the LTPP Customer Support Services.(79) It can be seen from the figures that, on average, the higher the longitudinal cracking length was before treatments, the lower the RSP was after treatments.

Table 40. Impacts of various maintenance treatments and control section on pavement performance in terms of RSP based on longitudinal cracking.

| Climatic Region | Treatment Type | Remaining Structural Period (Years) | Difference in RSP (Year) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Sections | Control Sections | |||||||||

| Number of Sections | Min | Max | Average | Number of Sections | Min | Max | Average | |||

| WF | Thin overlay | 23 | 2 | 20 | 9 | 12 | 4 | 19 | 12 | –3 |

| WNF | 26 | 5 | 20 | 12 | 20 | 0 | 18 | 12 | 0 | |

| DF | 12 | 2 | 20 | 15 | 6 | 5 | 18 | 14 | 1 | |

| DNF | 2 | 15 | 15 | 15 | 2 | 10 | 16 | 13 | 2 | |

| WF | Slurry seal | 13 | 3 | 20 | 10 | 12 | 4 | 19 | 12 | –2 |

| WNF | 30 | 4 | 20 | 13 | 20 | 0 | 18 | 13 | 0 | |

| DF | 10 | 8 | 20 | 16 | 6 | 5 | 18 | 14 | 2 | |

| DNF | 1 | 16 | 16 | 16 | 2 | 10 | 16 | 13 | 3 | |

| WF | Crack seal | 12 | 0 | 20 | 7 | 12 | 4 | 19 | 12 | –5 |

| WNF | 14 | 1 | 20 | 13 | 20 | 0 | 18 | 12 | 1 | |

| DF | 7 | 1 | 20 | 13 | 6 | 5 | 18 | 14 | –1 | |

| DNF | 1 | 2 | 2 | 2 | 2 | 10 | 16 | 13 | –11 | |

| WF | Aggregate seal coat | 21 | 3 | 20 | 10 | 12 | 4 | 19 | 12 | –2 |

| WNF | 19 | 5 | 20 | 14 | 20 | 0 | 18 | 12 | 2 | |

| DF | 9 | 8 | 20 | 18 | 6 | 5 | 18 | 14 | 4 | |

| DNF | 1 | 20 | 20 | 20 | 2 | 10 | 16 | 13 | 7 | |

| Max = Maximum. Min = Minimum. |

||||||||||

Listed in table 41 are the calculated minimum, maximum, and average RSPs based on transverse cracking for the SPS-3 test sections that were subjected to the same treatment type and located in the same climatic region. The table also includes the same data for the associated control sections. The data in the table indicate the following:

For each treatment type, the RSPs of the test sections after treatment were plotted against the last measured transverse cracking data point before treatment were submitted to FHWA and are available from the LTPP Customer Support Services.(79) It can be seen from the figures that the lower the cumulative transfer cracks value was, the higher the RSP was after treatment.

Table 41. Impacts of various maintenance treatments and control section on pavement performance in terms of RSP based on transverse cracking.

| Climatic Regions | Treatment Type | Remaining Structural Period (Years) | Difference in RSP (Year) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Sections | Control Sections | |||||||||

| Number of Sections | Min | Max | Average | Number of Sections | Min | Max | Average | |||

| WF | Thin overlay | 22 | 1 | 20 | 9 | 18 | 0 | 16 | 8 | 1 |

| WNF | 24 | 5 | 20 | 12 | 20 | 3 | 17 | 12 | 0 | |

| DF | 12 | 2 | 20 | 13 | 8 | 0 | 18 | 11 | 2 | |

| DNF | 2 | 12 | 20 | 16 | 1 | 4 | 4 | 4 | 12 | |

| WF | Slurry seal | 14 | 0 | 20 | 8 | 18 | 0 | 16 | 8 | 0 |

| WNF | 30 | 3 | 20 | 12 | 20 | 3 | 17 | 12 | 0 | |

| DF | 7 | 2 | 20 | 13 | 8 | 0 | 18 | 11 | 2 | |

| DNF | 1 | 9 | 9 | 9 | 1 | 4 | 4 | 4 | 5 | |

| WF | Crack seal | 14 | 0 | 20 | 8 | 18 | 0 | 16 | 8 | 0 |

| WNF | 18 | 0 | 20 | 12 | 20 | 3 | 16 | 12 | 0 | |

| DF | 9 | 0 | 20 | 12 | 8 | 0 | 18 | 11 | 1 | |

| DNF | 0 | 0 | 0 | — | 1 | 4 | 4 | 4 | NC | |

| WF | Aggregate seal coat | 17 | 0 | 20 | 10 | 18 | 0 | 16 | 8 | 2 |

| WNF | 16 | 3 | 20 | 13 | 20 | 3 | 16 | 12 | 1 | |

| DF | 8 | 1 | 20 | 12 | 8 | 0 | 18 | 11 | 1 | |

| DNF | 1 | 9 | 9 | 9 | 1 | 4 | 4 | 4 | 5 | |

| — Indicates no data. NC = Could not be compared. |

||||||||||

Table 42 summarizes the impacts of the four SPS-3 maintenance treatments on the pavement performance.

Table 42. Summary of the impact of treatment type on pavement performance compared with the control sections (years).

| Treatment Type | Condition or Distress Type | Climatic Region | |||

|---|---|---|---|---|---|

| WF | WNF | DF | DNF | ||

| Thin overlay | IRI | 5 | 4 | 5 | –2 |

| Rut depth | 7 | 8 | 7 | –1 | |

| Alligator cracking | 2 | 2 | –1 | –9 | |

| Longitudinal cracking | –3 | 0 | 1 | 2 | |

| Transverse cracking | 1 | 0 | 2 | 12 | |

| Slurry seal | IRI | 1 | 4 | 1 | 4 |

| Rut depth | 2 | 5 | 4 | 3 | |

| Alligator cracking | –1 | 0 | –3 | –7 | |

| Longitudinal cracking | –2 | 0 | 2 | 3 | |

| Transverse cracking | 0 | 0 | 2 | 5 | |

| Crack seal | IRI | 0 | 2 | 3 | 3 |

| Rut depth | 1 | 5 | 7 | 2 | |

| Alligator cracking | –2 | –1 | 1 | –15 | |

| Longitudinal cracking | –5 | 1 | –1 | –11 | |

| Transverse cracking | 0 | 0 | 1 | NC | |

| Aggregate seal coat | IRI | 2 | 4 | 1 | –4 |

| Rut depth | 3 | 3 | 5 | 9 | |

| Alligator cracking | 2 | 2 | –1 | 1 | |

| Longitudinal cracking | –2 | 2 | 4 | 7 | |

| Transverse cracking | 2 | 1 | 1 | 5 | |

| NC = Could not be compared. | |||||

The number in each cell of the table expresses the average increase in RFP or RSP of the test sections compared with the control sections. It should be noted that the sections in the DNF region were too few in number to draw any reliable conclusions. Also, in many instances, the control sections were not truly representative of the test sections that had undergone treatments in terms of pavement condition and distress. Nevertheless, the data in the table indicate the following:

In general, the worse the pavement conditions were before treatment, the shorter the benefits of treatment were in terms of RFP or RSP.

Once again, one of the objectives of this study was to analyze the benefits of the various rehabilitation treatments applied to the SPS-5 test sections. Unfortunately, for some test sections, the LTPP database did not have enough time-series pavement condition and distress data to conduct the analyses. In one scenario, some of the test sections were subjected to a second treatment and only one or two data points were available. In another scenario, the measured IRI, rut depth, and/or cracking data showed improvement in the pavement condition and/or distresses over time without treatment. After an exhaustive search of the database, it was found that the database had an adequate number of time-series pavement condition and distress data for the evaluation of the benefits of the following rehabilitation treatments:

After identifying the types of treatments that could be analyzed, the time-dependent pavement condition and distress data were then organized per treatment type, climatic region, and per pavement condition and distress type. The data were then analyzed, RFPs and RSPs of each treated test section accepted for analyses, and the corresponding control and/or linked sections were calculated. For each pavement condition (IRI) and distress type (rut depth and alligator, longitudinal, and transverse cracking), RFP/RSP of the treatment and the treatment benefits are listed in table 43 through table 52. The benefits are listed per climatic region and pavement condition and distress type and are summarized in table 53. The summary of the treatment benefits listed in table 53 is divided based on the pavement condition and distress type and on the treatment type. However, the discussion that follows that table is based on the benefits for the pavement condition and distress type.

Table 43. Impacts of various treatments and control section on pavement performance in terms of RFP based on IRI for virgin AC mixes (years).

| Climatic Region | State (Code) | Control Section RFP (Years) | Virgin AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RFP | B1 | B2 | RFP | B1 | B2 | RFP | B1 | B2 | RFP | B1 | B2 | |||

| WF | Maine (23) | 17 | 20 | 3 | 20 | 20 | 3 | 20 | 20 | 3 | 20 | 20 | 3 | 20 |

| Minnesota (27) | 5 | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| New Jersey (34) | 10 | 20 | 10 | 20 | 20 | 10 | 20 | 20 | 10 | 20 | 20 | 10 | 20 | |

| Alberta (81) | 16 | ND | — | ND | 20 | 4 | 20 | 20 | 4 | 20 | 20 | 4 | 20 | |

| Manitoba (83) | ND | 20 | — | 18 | 20 | — | 19 | NS | — | NS | 20 | — | 20 | |

| WNF | Alabama (1) | 15 | 20 | 5 | 18 | 20 | 5 | 20 | 20 | 5 | 20 | 20 | 5 | 20 |

| Florida (12) | 12 | 20 | 8 | 20 | 20 | 8 | 20 | 20 | 8 | 20 | 20 | 8 | 20 | |

| Georgia (13) | NCS | 20 | — | 20 | 20 | — | 15 | 20 | — | 18 | 20 | — | 12 | |

| Maryland (24) | 18 | 20 | 2 | 11 | 15 | –3 | 12 | 20 | 2 | 20 | 20 | 2 | 20 | |

| Mississippi (28) | 13 | 20 | 7 | 6 | 20 | 7 | 20 | 20 | 7 | 12 | 20 | 7 | 20 | |

| Missouri (29) | ND | NS | — | NS | NS | — | NS | NS | — | NS | NS | — | NS | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | ND | 20 | — | 10 | NS | — | NS | NS | — | NS | NS | — | NS | |

| DF | Colorado (8) | ND | NS | — | NS | 20 | — | 20 | 17 | — | ND | 20 | — | ND |

| Montana (30) | 4 | 16 | 12 | 6 | 20 | 16 | 20 | 20 | 16 | 20 | 20 | 16 | N/A | |

| DNF | Arizona (4) | 17 | 20 | 3 | 20 | 20 | 3 | 20 | 20 | 3 | 20 | 20 | 3 | 20 |

| California (6) | 0 | 10 | 10 | 6 | 20 | 20 | 10 | 20 | 20 | 15 | 20 | 20 | 20 | |

| New Mexico (35) | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= Change in functional period (CFP). B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. N/A = Not applicable. |

||||||||||||||

Table 44. Impacts of various treatments and control section on pavement performance in terms of RFP based on IRI for recycled AC mixes (years).

| Climatic Region | State (Code) | Control Section RFP (Years) | Recycled AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RFP | B1 | B2 | RFP | B1 | B2 | RFP | B1 | B2 | RFP | B1 | B2 | |||

| WF | Maine (23) | 17 | NS | — | NS | NS | — | NS | NS | — | NS | NS | — | NS |

| Minnesota (27) | 5 | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| New Jersey (34) | 10 | 20 | 10 | 20 | 20 | 10 | 20 | 20 | 10 | 20 | 20 | 10 | 20 | |

| Alberta (81) | 16 | 20 | 4 | 18 | 20 | 4 | 20 | 20 | 4 | 17 | 20 | 4 | 20 | |

| Manitoba (83) | ND | 20 | — | 20 | NS | — | NS | 20 | — | 20 | 20 | — | 20 | |

| WNF | Alabama (1) | 15 | 20 | 5 | 17 | 20 | 5 | 20 | 20 | 5 | 20 | 20 | 5 | 10 |

| Florida (12) | 12 | 20 | 8 | 16 | 20 | 8 | 20 | 20 | 8 | 20 | 20 | 8 | 20 | |

| Georgia (13) | NCS | 20 | — | 15 | 20 | — | 15 | 20 | — | 14 | 20 | — | 11 | |

| Maryland (24) | 18 | ND | — | ND | 20 | 2 | 15 | 20 | 2 | 12 | 20 | 2 | 20 | |

| Mississippi (28) | 13 | 20 | 7 | 20 | 20 | 7 | 20 | 20 | 7 | 20 | 20 | 7 | 20 | |

| Missouri (29) | ND | NS | — | NS | NS | — | NS | NS | — | NS | NS | — | NS | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | ND | 20 | — | 15 | 20 | — | 20 | 20 | — | 20 | 20 | — | 16 | |

| DF | Colorado (8) | ND | 20 | — | 20 | NS | — | NS | 20 | — | ND | 20 | — | 20 |

| Montana (30) | 4 | 12 | 8 | 6 | 20 | 16 | 20 | 15 | 11 | 3 | 20 | 16 | 20 | |

| DNF | Arizona (4) | 17 | 13 | –4 | 8 | 20 | 3 | 20 | 16 | –1 | 14 | 20 | 3 | 20 |

| California (6) | 0 | 11 | 11 | 10 | 20 | 20 | 10 | 9 | 9 | 8 | 20 | 20 | 18 | |

| New Mexico (35) | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. |

||||||||||||||

Table 45. Impacts of various treatments and control section on pavement performance in terms of RFP/RSP based on rut depth for virgin AC mixes (years).

| Climatic Region | State (Code) | Control Section RFP/RSP (Years) | Virgin AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RFP/ RSP | B1 | B2 | RFP/ RSP | B1 | B2 | RFP/ RSP | B1 | B2 | RFP/ RSP | B1 | B2 | |||

| WF | Maine (23) | 0 | 20 | 20 | 20 | 12 | 11 | 15 | 8 | 8 | 13 | 10 | 10 | 11 |

| Minnesota (27) | 16 | NS | — | NS | NS | — | NS | NS | — | NS | NS | — | NS | |

| New Jersey (34) | NS | 20 | — | 20 | 20 | — | 20 | NS | — | NS | NS | — | NS | |

| Alberta (81) | ND | ND | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| Manitoba (83) | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| WNF | Alabama (1) | NS | 20 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND |

| Florida (12) | 12 | 20 | 8 | 20 | 20 | 8 | 20 | 20 | 8 | 20 | 20 | 8 | 20 | |

| Georgia (13) | NCS | 20 | — | 20 | 20 | — | 20 | 20 | — | 20 | 20 | — | 20 | |

| Maryland (24) | ND | NS | — | NS | 20 | — | 3 | NS | — | NS | 20 | — | 20 | |

| Mississippi (28) | 0 | 15 | 15 | 20 | 4 | 4 | 5 | 8 | 8 | 13 | 3 | 3 | 5 | |

| Missouri (29) | NS | 20 | — | 20 | 20 | — | 13 | 20 | — | 20 | 20 | — | 20 | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | 14 | 20 | 6 | 20 | 20 | 6 | 20 | 20 | 6 | 18 | 20 | 6 | 18 | |

| DF | Colorado (8) | NS | 20 | — | 13 | 20 | — | 13 | 20 | — | 20 | 18 | — | 20 |

| Montana (30) | NS | 20 | — | 20 | 14 | — | 7 | 10 | — | 10 | 17 | — | 13 | |

| DNF | Arizona (4) | NS | 20 | — | ND | NS | — | NS | NS | — | NS | NS | — | NS |

| California (6) | ND | 20 | — | 6 | 20 | — | 20 | 20 | — | 20 | 20 | — | 20 | |

| New Mexico (35) | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= Change in functional period. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. |

||||||||||||||

Table 46. Impacts of various treatments and control section on pavement performance in terms of RFP/RSP based on rut depth for recycled AC mixes (years).

| Climatic Region | State (Code) | Control Section RFP/RSP (Years) | Recycled AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RFP/ RSP | B1 | B2 | RFP/ RSP | B1 | B2 | RFP/ RSP | B1 | B2 | RFP/ RSP | B1 | B2 | |||

| WF | Maine (23) | 0 | 15 | 15 | 16 | 14 | 14 | 15 | 12 | 12 | 18 | 10 | 10 | 15 |

| Minnesota (27) | 16 | 20 | 4 | 20 | NS | — | NS | 20 | 4 | 20 | NS | — | NS | |

| New Jersey (34) | NS | 20 | — | 20 | NS | — | NS | NS | — | NS | NS | — | NS | |

| Alberta (81) | ND | NS | — | NS | 20 | — | ND | 20 | — | ND | NS | — | NS | |

| Manitoba (83) | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| WNF | Alabama (1) | NS | 20 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND |

| Florida (12) | 12 | 20 | 8 | 20 | 20 | 8 | 11 | 20 | 8 | 20 | 20 | 8 | 20 | |

| Georgia (13) | NCS | 20 | — | 20 | 20 | — | 20 | 20 | — | 20 | 20 | — | 20 | |

| Maryland (24) | ND | 4 | — | 1 | 2 | — | 0 | 9 | — | 2 | 3 | — | 1 | |

| Mississippi (28) | 0 | 9 | 9 | 20 | 6 | 6 | 12 | 9 | 9 | 20 | 4 | 4 | 9 | |

| Missouri (29) | NS | 20 | — | 20 | 20 | — | 3 | 20 | — | 20 | 20 | — | 1 | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | 14 | 20 | 6 | 20 | 20 | 6 | 20 | 20 | 6 | 20 | 20 | 6 | 20 | |

| DF | Colorado (8) | NS | 19 | — | 6 | 20 | — | 8 | 18 | — | 20 | 13 | — | 20 |

| Montana (30) | NS | 16 | — | 18 | 20 | — | 20 | 12 | — | 10 | 20 | — | 20 | |

| DNF | Arizona (4) | NS | 20 | — | ND | 20 | — | ND | 20 | — | ND | NS | — | NS |

| California (6) | ND | 20 | — | 20 | 20 | — | 11 | 20 | — | 20 | 20 | — | 20 | |

| New Mexico (35) | ND | NS | — | NS | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. |

||||||||||||||

Table 47. Impacts of various treatments and control section on pavement performance in terms of RSP based on alligator cracking for virgin AC mixes (years).

| Climatic Region | State (Code) | Control Section RSP (Years) | Virgin AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | |||

| WF | Maine (23) | 10 | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND |

| Minnesota (27) | 16 | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| New Jersey (34) | ND | 20 | — | 20 | 20 | — | 15 | 20 | — | 13 | 18 | — | 10 | |

| Alberta (81) | ND | ND | — | ND | 13 | — | ND | 11 | — | ND | 14 | — | ND | |

| Manitoba (83) | ND | 9 | — | 0 | 13 | — | 0 | 11 | — | 0 | 13 | — | 0 | |

| WNF | Alabama (1) | 0 | 20 | 20 | 0 | 20 | 20 | 15 | 20 | 20 | 20 | 20 | 20 | 20 |

| Florida (12) | 12 | 20 | 8 | 11 | 20 | 8 | 20 | 20 | 8 | 20 | 19 | 8 | 20 | |

| Georgia (13) | NCS | 20 | — | 9 | ND | — | ND | ND | — | ND | 20 | — | 10 | |

| Maryland (24) | ND | ND | — | ND | ND | — | ND | 20 | — | 20 | 20 | — | 20 | |

| Mississippi (28) | 16 | 12 | –4 | 7 | 10 | –6 | 9 | 10 | –6 | 5 | 9 | –7 | 9 | |

| Missouri (29) | NS | ND | — | ND | 8 | — | 6 | 9 | — | 8 | 10 | — | 7 | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | NS | NS | — | NS | NS | — | NS | ND | — | ND | 20 | — | NS | |

| DF | Colorado (8) | ND | 6 | — | 4 | 7 | — | 3 | 6 | — | 4 | 8 | — | 1 |

| Montana (30) | ND | NS | — | NS | ND | — | ND | 20 | — | 20 | ND | — | ND | |

| DNF | Arizona (4) | ND | 9 | — | ND | 20 | — | ND | 20 | — | ND | ND | — | ND |

| California (6) | ND | 5 | — | ND | 11 | — | ND | 8 | — | ND | 11 | — | ND | |

| New Mexico (35) | ND | 12 | — | 5 | ND | — | ND | 20 | — | 20 | 16 | — | 11 | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. |

||||||||||||||

Table 48. Impacts of various treatments and control section on pavement performance in terms of RSP based on alligator cracking for recycled AC mixes (years).

| Climatic Region | State (Code) | Control Section RSP (Years) | Recycled AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | |||

| WF | Maine (23) | 10 | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND |

| Minnesota (27) | 16 | ND | — | ND | ND | — | ND | 20 | 4 | — | ND | — | ND | |

| New Jersey (34) | ND | 11 | — | 19 | 15 | — | 0 | 12 | — | 0 | 17 | — | 1 | |

| Alberta (81) | ND | 7 | — | ND | 6 | — | ND | 7 | — | ND | 10 | — | ND | |

| Manitoba (83) | ND | 7 | — | 0 | 7 | — | 0 | 10 | — | 0 | 12 | — | 0 | |

| WNF | Alabama (1) | 0 | 16 | 16 | 4 | 20 | 20 | 20 | 20 | 20 | 10 | 20 | 20 | 20 |

| Florida (12) | 12 | 20 | 8 | 16 | 20 | 8 | 20 | 20 | 8 | 20 | 20 | 8 | 20 | |

| Georgia (13) | — | 20 | — | 20 | ND | — | ND | 20 | — | 16 | ND | — | ND | |

| Maryland (24) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Mississippi (28) | 16 | 7 | –10 | 0 | 11 | –5 | 5 | 6 | –10 | 0 | 9 | –8 | 4 | |

| Missouri (29) | NS | ND | — | ND | ND | — | ND | 20 | — | 17 | ND | — | ND | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | NS | 20 | — | NS | 20 | — | NS | 20 | — | NS | 20 | — | NS | |

| DF | Colorado (8) | ND | 6 | — | 0 | 6 | — | 4 | 20 | — | 0 | 7 | — | 5 |

| Montana (30) | ND | ND | — | ND | 3 | — | 7 | 4 | — | 5 | 6 | — | 6 | |

| DNF | Arizona (4) | ND | 4 | — | ND | 13 | — | ND | 15 | — | ND | 20 | — | ND |

| California (6) | ND | 4 | — | ND | 8 | — | ND | 3 | — | ND | 20 | — | ND | |

| New Mexico (35) | ND | 20 | — | 0 | 10 | — | 8 | 15 | — | 0 | 10 | — | 9 | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NS = Model has a negative slope. |

||||||||||||||

Table 49. Impacts of various treatments and control section on pavement performance in terms of RSP based on longitudinal cracking for virgin AC mixes (years).

| Climatic Region | State (Code) | Control Section RSP (Years) | Virgin AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | |||

| WF | Maine (23) | 8 | 9 | 0 | 8 | 9 | 1 | 8 | 9 | 1 | 8 | 9 | 1 | 9 |

| Minnesota (27) | 9 | 6 | –3 | 2 | 11 | 2 | 6 | 8 | –1 | 5 | 8 | –1 | 6 | |

| New Jersey (34) | ND | 20 | — | NA | 15 | — | NA | 18 | — | NA | 12 | — | NA | |

| Alberta (81) | ND | ND | — | ND | 20 | — | ND | 20 | — | ND | 17 | — | ND | |

| Manitoba (83) | ND | 20 | — | 0 | 14 | — | 0 | 20 | — | 0 | 17 | — | 0 | |

| WNF | Alabama (1) | ND | 20 | — | 6 | 20 | — | 0 | 20 | — | 8 | 20 | — | 0 |

| Florida (12) | ND | 20 | — | 0 | 20 | — | 0 | 17 | — | 14 | 20 | — | 14 | |

| Georgia (13) | NCS | 11 | — | 0 | 14 | — | 0 | 13 | — | 0 | 14 | — | 0 | |

| Maryland (24) | ND | ND | — | ND | ND | — | ND | 13 | — | 0 | 12 | — | 3 | |

| Mississippi (28) | 9 | 20 | 11 | 0 | 12 | 2 | 1 | 14 | 5 | 5 | ND | — | ND | |

| Missouri (29) | 4 | 5 | 1 | 5 | 10 | 6 | 10 | 10 | 5 | 10 | 18 | 13 | 19 | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | NS | 11 | — | ND | 20 | — | ND | 17 | — | ND | 20 | — | ND | |

| DF | Colorado (8) | ND | 5 | — | 4 | 6 | — | 4 | 7 | — | 5 | 9 | — | 6 |

| Montana (30) | ND | NS | — | NS | ND | — | ND | 10 | — | 9 | ND | — | ND | |

| DNF | Arizona (4) | ND | 20 | — | ND | 18 | — | ND | 20 | — | ND | 20 | — | ND |

| California (6) | ND | 11 | — | ND | 11 | — | ND | 10 | — | ND | 16 | — | ND | |

| New Mexico (35) | ND | 12 | — | 7 | 10 | — | 8 | 11 | — | 5 | 10 | — | 8 | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. |

||||||||||||||

Table 50. Impacts of various treatments and control section on pavement performance in terms of RSP based on longitudinal cracking for recycled AC mixes (years).

| Climatic Region | State (Code) | Control Section RSP (Years) | Recycled AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | |||

| WF | Maine (23) | 8 | 10 | 2 | 10 | 9 | 0 | 8 | 10 | 2 | 10 | 9 | 1 | 9 |

| Minnesota (27) | 9 | 9 | 0 | 3 | 20 | 11 | 11 | 9 | 1 | 7 | 13 | 5 | 10 | |

| New Jersey (34) | ND | NS | — | NS | 12 | — | N/A | NS | — | NS | 12 | — | N/A | |

| Alberta (81) | ND | 13 | — | ND | 14 | — | ND | 12 | — | ND | 13 | — | ND | |

| Manitoba (83) | ND | NS | — | NS | 20 | — | 0 | 20 | — | 0 | 16 | — | 0 | |

| WNF | Alabama (1) | ND | 20 | — | 20 | 20 | — | 0 | 20 | — | 0 | 20 | — | 0 |

| Florida (12) | ND | 20 | — | 20 | 19 | — | 19 | 20 | — | 1 | 20 | — | 18 | |

| Georgia (13) | NCS | 11 | — | 1 | 14 | — | 0 | 13 | — | 0 | 14 | — | 0 | |

| Maryland (24) | ND | 7 | — | 5 | ND | — | ND | 16 | — | 7 | 20 | — | 6 | |

| Mississippi (28) | 9 | 20 | 11 | 4 | 20 | 11 | 0 | 9 | 0 | 7 | 14 | 5 | 0 | |

| Missouri (29) | 4 | 13 | 9 | 10 | 10 | 5 | 7 | 13 | 9 | 6 | 13 | 8 | 11 | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | NS | 10 | — | ND | 12 | — | ND | 12 | — | ND | 12 | — | ND | |

| DF | Colorado (8) | ND | 7 | — | 4 | 6 | — | 4 | 7 | — | 6 | 6 | — | 5 |

| Montana (30) | ND | ND | — | ND | ND | — | ND | ND | — | ND | 19 | — | 8 | |

| DNF | Arizona (4) | ND | NS | — | NS | 19 | — | ND | 20 | — | ND | 18 | — | ND |

| California (6) | ND | 10 | — | ND | 10 | — | ND | 8 | — | ND | 9 | — | ND | |

| New Mexico (35) | ND | 10 | — | 9 | 8 | — | 6 | 10 | — | 6 | 8 | — | 5 | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. N/A = Not applicable. |

||||||||||||||

Table 51. Impacts of various treatments and control section on pavement performance in terms of RSP based on transverse cracking for virgin AC mixes (years).

| Climatic Region | State (Code) | Control Section RSP (Years) | Virgin AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | |||

| WF | Maine (23) | NS | ND | — | ND | 11 | — | 10 | 11 | — | 10 | ND | — | ND |

| Minnesota (27) | 16 | 2 | –15 | 5 | 13 | –4 | 15 | 6 | –10 | 13 | 13 | –3 | 14 | |

| New Jersey (34) | ND | 18 | — | 5 | 20 | — | 15 | 20 | — | 13 | 20 | — | 14 | |

| Alberta (81) | ND | ND | — | ND | 20 | — | ND | 17 | — | ND | 11 | — | ND | |

| Manitoba (83) | ND | 20 | — | 0 | 10 | — | 2 | 20 | — | 0 | 14 | — | 0 | |

| WNF | Alabama (1) | 10 | 20 | 10 | 0 | 20 | 10 | 11 | 20 | 10 | 9 | 20 | 10 | 4 |

| Florida (12) | ND | 19 | — | 7 | 20 | — | 7 | 20 | — | 0 | 20 | — | 2 | |

| Georgia (13) | NCS | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Maryland (24) | ND | ND | — | ND | ND | — | ND | 20 | — | 5 | 20 | — | 20 | |

| Mississippi (28) | 8 | 12 | 4 | 6 | 11 | 3 | 9 | 14 | 6 | 5 | 13 | 5 | 11 | |

| Missouri (29) | NS | 9 | — | 8 | ND | — | ND | 10 | — | 9 | 14 | — | 11 | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | NS | 12 | — | ND | 20 | — | ND | 20 | — | ND | 20 | — | ND | |

| DF | Colorado (8) | ND | 10 | — | 6 | 10 | — | 8 | 15 | — | 5 | NS | — | NS |

| Montana (30) | ND | 20 | — | 20 | 20 | — | 20 | 20 | — | 20 | 20 | — | 20 | |

| DNF | Arizona (4) | ND | 14 | — | ND | 19 | — | ND | 19 | — | ND | 19 | — | ND |

| California (6) | ND | 9 | — | ND | 12 | — | ND | 9 | — | ND | 13 | — | ND | |

| New Mexico (35) | ND | 15 | — | 10 | ND | — | ND | 12 | — | 11 | 17 | — | 16 | |

| — Indicates could not be estimated. Thin = 2 inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. N/A = Not applicable. |

||||||||||||||

Table 52. Impacts of various treatments and control section on pavement performance in terms of RSP based on transverse cracking for recycled AC mixes (years).

| Climatic Region | State (Code) | Control Section RSP (Years) | Recycled AC Mix | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overlay | Mill and Fill | |||||||||||||

| Thin | Thick | Thin | Thick | |||||||||||

| RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | RSP | B1 | B2 | |||

| WF | Maine (23) | NS | ND | — | ND | ND | — | ND | 20 | — | 9 | ND | — | ND |

| Minnesota (27) | 17 | 8 | –8 | 5 | 13 | –4 | 9 | 10 | –7 | 7 | 9 | –8 | 8 | |

| New Jersey (34) | ND | 13 | — | 1 | 17 | — | 8 | 20 | — | 0 | 20 | — | 10 | |

| Alberta (81) | ND | 12 | — | ND | 14 | — | ND | 9 | — | ND | 9 | — | ND | |

| Manitoba (83) | ND | 17 | — | 0 | 17 | — | 0 | 20 | — | 0 | 8 | — | 6 | |

| WNF | Alabama (1) | 10 | 19 | 9 | 0 | 20 | 10 | 7 | 20 | 10 | 2 | 20 | 10 | 7 |

| Florida (12) | ND | 20 | — | 14 | ND | — | ND | 20 | — | 10 | 20 | — | 20 | |

| Georgia (13) | NCS | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Maryland (24) | ND | 14 | — | 10 | 8 | — | 7 | 20 | — | 20 | ND | — | ND | |

| Mississippi (28) | 8 | 8 | 0 | 6 | 9 | 1 | 3 | 10 | 2 | 7 | 10 | 2 | 5 | |

| Missouri (29) | NS | ND | — | ND | ND | — | ND | 20 | — | 15 | ND | — | ND | |

| Oklahoma (40) | ND | ND | — | ND | ND | — | ND | ND | — | ND | ND | — | ND | |

| Texas (48) | NS | 11 | — | ND | 15 | — | ND | 13 | — | ND | 17 | — | ND | |

| DF | Colorado (8) | ND | 6 | — | 4 | ND | — | ND | 6 | — | 4 | ND | — | ND |

| Montana (30) | ND | ND | — | ND | 20 | — | 20 | ND | — | ND | NS | — | NS | |

| DNF | Arizona (4) | ND | NS | — | NS | 8 | — | ND | 9 | — | ND | 11 | — | ND |

| California (6) | ND | 10 | — | ND | 10 | — | ND | 8 | — | ND | 8 | — | ND | |

| New Mexico (35) | ND | 17 | — | 3 | 15 | — | 8 | 17 | — | 2 | 11 | — | 9 | |

| — Indicates could not be estimated. Thin = 2-inches (51 mm). Thick = 4 inches (102 mm). B1= CFP. B2 = Functional condition reoccurrence period. ND = No data. NCS = No control section. NS = Model has a negative slope. |

||||||||||||||

Table 53. Summary of benefits of various rehabilitation treatments (years).

| Treatment Type | Thickness (Inches) | Statistic | Condition | Distress | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rut Depth | Cracking | |||||||||||

| IRI | Alligator | Longitudinal | Transverse | |||||||||

| B1 | B2 | B1 | B2 | B1 | B2 | B1 | B2 | B1 | B2 | |||

| Overlay, virgin AC mix | 2 | Min | 2 | 6 | 6 | 6 | –4 | 0 | –3 | 0 | –15 | 0 |

| Max | 12 | 20 | 20 | 20 | 20 | 20 | 11 | 8 | 10 | 20 | ||

| Average | 7 | 14 | 12 | 18 | 8 | 7 | 2 | 3 | 0 | 7 | ||

| 4 | Min | –3 | 10 | 4 | 3 | –6 | 0 | 1 | 0 | –4 | 2 | |

| Max | 20 | 20 | 11 | 20 | 20 | 20 | 6 | 10 | 10 | 20 | ||

| Average | 7 | 18 | 7 | 14 | 7 | 10 | 3 | 4 | 3 | 11 | ||

| Overlay, recycled AC mix | 2 | Min | –4 | 6 | 4 | 1 | –10 | 0 | 0 | 1 | –8 | 0 |

| Max | 11 | 20 | 15 | 20 | 16 | 20 | 11 | 20 | 9 | 14 | ||

| Average | 6 | 15 | 8 | 17 | 5 | 7 | 5 | 9 | 0 | 5 | ||

| 4 | Min | 2 | 10 | 6 | 0 | –5 | 0 | 0 | 0 | –4 | 0 | |

| Max | 20 | 20 | 14 | 20 | 20 | 20 | 11 | 19 | 10 | 20 | ||

| Average | 8 | 18 | 9 | 12 | 8 | 8 | 7 | 6 | 2 | 8 | ||

| Mill and fill, virgin AC mix | 2 | Min | 2 | 12 | 6 | 10 | –6 | 0 | –1 | 0 | –10 | 0 |

| Max | 20 | 20 | 8 | 20 | 20 | 20 | 5 | 14 | 10 | 20 | ||

| Average | 8 | 19 | 8 | 17 | 7 | 13 | 2 | 6 | 2 | 8 | ||

| 4 | Min | 2 | 12 | 3 | 5 | –7 | 0 | –1 | 0 | –3 | 0 | |

| Max | 20 | 20 | 10 | 20 | 20 | 20 | 13 | 19 | 10 | 20 | ||

| Average | 8 | 19 | 7 | 17 | 7 | 11 | 4 | 6 | 4 | 11 | ||

| Mill and fill, recycled AC mix | 2 | Min | –1 | 3 | 4 | 2 | –10 | 0 | 0 | 0 | –7 | 0 |

| Max | 11 | 20 | 12 | 20 | 20 | 20 | 9 | 10 | 10 | 20 | ||

| Average | 6 | 16 | 8 | 17 | 6 | 7 | 3 | 5 | 2 | 7 | ||

| 4 | Min | 2 | 10 | 4 | 1 | –8 | 0 | 1 | 0 | –7 | 5 | |

| Max | 20 | 20 | 10 | 20 | 20 | 20 | 8 | 18 | 10 | 20 | ||

| Average | 8 | 18 | 7 | 15 | 7 | 8 | 5 | 6 | 2 | 9 | ||

| 1 inch = 25.4 mm. B1 = Changes in functional or structural period (CFP/CSP) in years. B2 = Functional or structural condition reoccurrence period (FCROP/SCROP) in years. Max = Maximum. Min = Minimum. |

||||||||||||

The benefits data listed in table 53 under the heading “IRI” indicate that the averages of the CFPs (labeled “B1” in the table) of all eight treatments were similar and equaled about 7 years. This was expected because a proper construction of 2- and 4-inch (51‑and 102-mm) overlays and 2- and 4-inch (51- and 102-mm) mill-and-fill treatments result in smooth pavement surface and almost the same rate of deterioration. Further, the average functional condition reoccurrence period (FCROP) in years of any of the eight treatments was about 17 years (i.e., 17 years after applying any of the eight treatments, the IRI of the treated pavement would be the same as it was just before treatment).

The benefits data listed in table 53 under the heading “Rut Depth” indicate that the benefits in terms of RSP (column labeled “B1”) and the structural condition reoccurrence period (SCROP) (column labeled “B2”) for AC overlays and mill-and-fill treatments using virgin and recycled asphalt mixes were statistically similar. Note that the SCROP is the same as TL as previously defined.(5)

The benefits data listed in table 53 under the heading “Alligator Cracking” indicate that the B1s of the eight treatments varied slightly depending on the thickness of the overlay and the type of the AC mix. On average, each treatment caused an increase in RSP of about 6 years. (This varied from a high of 20 years to a low of 10 years.) The latter was mainly the result of the condition of the control sections (i.e., no alligator cracking). Thus, the minimum and maximum change in structural period (CSP) should not be taken seriously; they are for information only. The average CSP, on the other hand, was a good measure of the benefits of each treatment. Further, the average structural period of the 2-inch (51-mm)-thick virgin AC overlay was 1 to 3 years lower than the 4inch (102-mm) virgin AC overlay. The type of AC mix (virgin and recycled) appeared not to affect the SCROP.

The benefits data listed in table 53 under the heading “Longitudinal Cracking” indicate that the average CFP/CSP of the test sections subjected to 2- and 4-inch (51- and 102-mm)-thick overlays and mill and fill treatments using virgin and recycled AC mixes appeared to have had the lowest CSPs (2 to 4 years), while the CSP for the recycled mixes was about 2 years longer. Further, the average SCROP of each of the four mill-and-fill treatments was about 6 years.

The benefits data listed in table 53 under the heading “Transverse Cracking” varied and depended on the thickness of the AC overlay. The 2-inch (51-mm)-thick AC overlay yielded a CSP of 0 years, whereas the 4-inch (102-mm) AC overlay yielded, on average, a CSP of 3 years. This was expected because the thin 2-inch (51-mm)-thick overlay has minor resistance to reflective cracking. The average SCROP of the 2-inch (51-mm)-thick overlay or mill and fill was about 7years, whereas the average SCROP of the 4-inch (102-mm) overlay or mill and fill was about 10 years.

Based on data availability in the LTPP database, eight rehabilitation treatments were included in the analyses of the treatment benefits. The benefits were estimated by comparing RFP and RSP of the test sections and RFP and RSP (CFP/CSP) of the control or linked sections. In addition, the FCROP/SCROP (the time in years from the treatment to the year during which the pavement condition or distresses are the same as those before treatment) were also used as calculated indicators of benefits. Based on the results of the analyses, the following conclusions were drawn:

Based on the results of the data, the research team strongly recommends the following:

The LTPP GPS-6 experiment contained flexible pavement test sections that were overlain prior to their assignment to the LTPP Program. The experiment also included test sections that were moved from other LTPP experiments after they were subjected to either AC overlay or mill-and-fill treatments. The test sections in the GPS-6 experiment were classified as GPS-6A, -6B, -6C,

-6D, and -6S. The following list explains each of the classifications:

After an extensive search of the database, all of the test sections in the GPS-6 experiment that had three or more before treatment and three or more after treatment time-series pavement condition and/or distress data points were grouped according to the following variables:

Therefore, the analyses were conducted to assess the impacts of each treatment type and AC mix type and thickness on the pavement performance (IRI, rut depth, and cracking) in each climatic region using RFP and RSP of each treated test section before and after treatment.

For each test section, the treatment benefits were expressed in terms of the CFP or CSP, which were the difference between the after treatment RFP or RSP and the before treatment RFP or RSP. The minimum and maximum CFPs and CSPs and their averages for all test sections located in the same climatic region were calculated and listed in table 54 through table 58 depending on the pavement condition and distress type. The data in the five tables are discussed in the follow subsections per pavement condition and distress type.

Table 54. Impacts of various treatments on pavement performance in terms of CFP based on IRI (years).

| Treatment Type | Mix Type | Thickness | Climatic Regions | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF | WNF | DF | DNF | |||||||||||||||

| No. | CFP (Year) | No. | CFP (Year) | No. | CFP (Year) | No. | CFP (Year) | |||||||||||

| Min | Max | Avg | Min | Max | Avg | Min | Max | Avg | Min | Max | Avg | |||||||

| Overlay | Virgin | Thin | 6 | 4 | 20 | 11 | 16 | 6 | 17 | 10 | 3 | 6 | 17 | 12 | 0 | 0 | 0 | — |

| Thick | 6 | 5 | 20 | 13 | 5 | 10 | 14 | 12 | 4 | 3 | 20 | 13 | 1 | 14 | 14 | 14 | ||

| Recycled | Thin | 0 | 0 | 0 | — | 4 | 2 | 20 | 10 | 0 | 0 | 0 | — | 0 | 0 | 0 | — | |

| Thick | 1 | 13 | 13 | 13 | 3 | 4 | 14 | 8 | 1 | –6 | –6 | –6 | 0 | 0 | 0 | — | ||