Precast Bent System for High Seismic Regions: Laboratory Tests of Column-to-Drilled Shaft Socket Connections

INTRODUCTION

The Need for Rapid Construction

Bridge substructures are most commonly constructed of cast-in-place concrete. Despite having some clear advantages (e.g., ease of transportation and to making continuous connections), cast-in-place concrete has two main drawbacks: long on-site construction times and large labor requirements in the field, which can result in high construction costs. Using cast-in-place construction for bridge replacement is particularly disruptive when it exacerbates traffic congestion. Therefore, there is an urgent need to develop methods for accelerating bridge construction.

Using precast bridge elements is one solution for reducing on-site construction time, field labor requirements, and traffic delays. Although large substructures (and even full bridges) can be constructed off-site, precast elements are usually limited to beams and columns to make fabrication and transportation easier. The quality of the individual precast elements cast in a factory often exceeds the quality of elements cast in the field. However, maintaining quality in the on-site connections between these precast elements is more difficult. Achieving good connections is particularly challenging in seismically hazardous areas, like the Pacific Northwest, in which the largest forces are developed at the beam-to-column or column-to-footing connections. Therefore, it is vital to develop economical connections that are strong enough to resist seismic excitation and easy to construct with high quality.

Socket Connection Concept

A lot of research has been performed on precast bridge connections, but mainly for applications in which the seismic demands are low.(1) Less research has been performed for applications in seismically active regions. Hieber et al. summarized the state of the art in this area in 2005.(2) Since then, Hieber et al. performed numerical analyses of precast piers, and Wacker et al. developed displacement and force-based design procedures.(3,4)

In 2008, Pang et al. proposed using "large-bar" connections to connect beams and columns.(5) They proposed to connect the elements with a small number of large bars that would fit into large ducts. Steuck et al. showed that bars as large as No. 18 could be anchored within the typical depth of a cap beam.(6,7) Cohagen et al. later proposed using unbonded post-tension strands to help re-center the column after the earthquake.(8) In 2011, Restrepo et al. summarized the development of a precast concrete bent-cap system for seismic regions.(9) Haraldsson developed the concept of using a socket connection to connect the base of a precast column with a cast-in-place spread footing.(10)

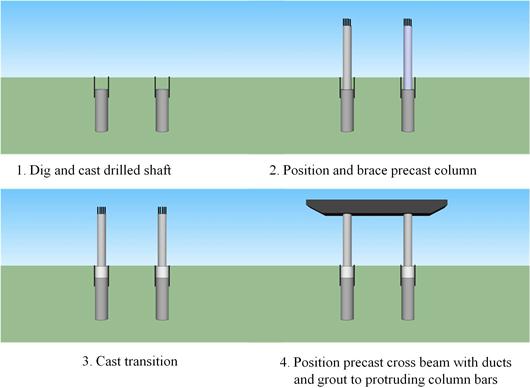

This report adapts the column-to-foundation socket concept to connections between a precast column and cast-in-place drilled shaft, which has a lot of benefit in bridge construction in urban areas. In this connection, the bottom of the precast column is roughened, where it will be embedded in the drilled shaft.

The construction stages are shown in figure 1.

Research Objectives and Scope

The objective of this research is to evaluate the behavior of precast column-to-drilled shaft connections. Particular emphasis is placed on inelastic behavior under cyclic excitations that may occur during a severe earthquake. Experimental and analytical studies of the behavior of the connection are described. The behavior is discussed with respect to quasi-static hysteretic behavior under cyclic loads.

This research was designed to answer the following questions:

- Does the column-to-drilled shaft connection behave like a non-contact lap splice, as assumed in the Washington State Department of Transportation (WSDOT) Bridge Design Manual (BDM)?(11)

- Does the WSDOT BDM design formula for proportioning transverse reinforcement of the shaft transition result in acceptable seismic response?

- Do the three wraps of spiral at the end of the shaft work like anchorage or undergo large lateral force transmitted by the column?

Two scaled (1/3.6) tests were performed. One specimen was designed to satisfy the current design specifications for cast-in-place systems, as described in the following references:

- American Association of State Highway and Transportation Officials (AASHTO) Load and Resistance Factor Design (LRFD) Bridge Design Specifications.(12)

- AASHTO Seismic Guide Specifications.(13)

- WSDOT BDM.(11)

The second specimen was designed similarly, except that the spiral in the shaft was reduced by half, with the intention that the specimen would fail in the shaft.