Previous Chapter « Table of Contents » Next Chapter

Auckland Regional Council (2004). DRAFT: The Use of Flocculants and Coagulants to Aid Suspended Sediment Settlement in Earthworks Runoff - Trials, Methodology and Design, Technical Publication No. 227, DRAFT June 2004, ISSN 1175-205X, ISBN 1-877353-31-0, http://www.arc.govt.nz/library/l35022_2.pdf

California Regional Water Quality Control Board - Central Valley Region (2005). Monitoring Requirements for Storm Water Treatment Systems that Utilize Chemical Additives to Enhance Sedimentation, Letter to Project Owners/Developers, 3 p. https://www.waterboards.ca.gov/centralvalley/HomePageAttachments/AdvTrtmnt2005.pdf

Caltrans (2003). BMP SE-11, in: Stormwater Quality Handbooks - Construction Site Best Management Practices (BMPs) Manual, State of California Department of Transportation (Caltrans), January 2003. https://www.dot.ca.gov/hq/construc/stormwater/CSBMPM_303_Final.pdf

Caltrans (2004). BMP NS-02, Dewatering Operations, State of California Department of Transportation (Caltrans), Updated March 2004. https://www.dot.ca.gov/hq/construc/stormwater/NS02Update.pdf

City of Redmond (2005). Summary Report: Field Experience with Alternative Construction Stormwater Treatment Technologies, HDR/EES, February, 2005.

Oregon Department of Environmental Quality (2004). BMP#34 - Flocculants & Coagulants, In: Best Management Practices for Stormwater Discharges Associated with Construction Activities, Oregon DEQ Northwest Region Document, August, 2004. http://www.oregondeq.com/nwr/WQConstructionBMPs.pdf

Washington State Department of Ecology (2005). BMP C250: Construction Stormwater Chemical Treatment, in: Stormwater Management Manual for Western Washington, Volume II - Construction Stormwater Pollution Prevention, Washington State Department of Ecology, February 2005. http://www.ecy.wa.gov/pubs/0510030.pdf

McLaughlin, R. A. (2006). SoilFacts: Using Baffles to Improve Sediment Basins. N.C. State University Extension SoilFacts Publication AGW-439-59. http://www.soil.ncsu.edu/publications/Soilfacts/AGW-439-59/AGW_439_59.pdf

McLaughlin, R. A. (2007). SoilFacts: Chemical Treatment to Control Turbidity on Construction Sites. N. C. State University Extension SoilFacts Publication AGW-439-62. http://www.soil.ncsu.edu/publications/Soilfacts/AG-439-62/AG-439-62_lo_res.pdf

North Carolina Department of the Environment and Natural Resources (2006). Erosion and Sediment Control Planning and Design Manual. Section 6.84: Flocculants. http://www.dlr.enr.state.nc.us/pages/manualsandvideos.html

Sojka, R. E., D. L. Bjorneberg, J. A. Entry, R. D. Lentz and W. J. Orts (2007). Polyacrylamide in Agriculture and Environmental Land Management. Adv. Agron. 92: 75-162.

There are many chemicals which are used to reduce suspended sediment in water. Each has its own benefits, costs, and risks for a particular application. In most cases, simple "shake" or batch tests are conducted to determine which chemical or combination of chemicals is most effective. Using any of these in CTS may be subject to local, state, or federal requirements for maximum use rates, aquatic toxicity data, or effluent toxicity testing. These requirements should be identified prior to selecting which flocculant to use on the site. The following are chemicals which have been used or tested in CTS for stormwater or similar environmental applications. The list is not intended to be exhaustive but to provide examples of the most common options in CTS. The list is separated into two sections: one for polymers and one for other additives.

Chitosan - A cationic polymer made from chitin, which is derived from crab, shrimp, and other crustacean shells, can be used in CTS. Although a cationic polymer such as chitosan can be toxic to fish (as the gills of a fi sh have a negative charge), free polymer is unlikely to be released through a CTS described herein because it binds quickly to the suspended sediment in the untreated runoff. Even if free chitosan were released to surface water, it would immediately bind to any sediment in the surface water further decreasing the likelihood of adversely affecting aquatic life. In the state of Washington, where chitosan has been used widely on all types of construction projects since 2000, including DOT projects, there have been no incidences of harm to the environment.

Polyacrylamide (PAM) - A synthetic polymer, PAM is used to describe a wide variety of chemicals based on the acrylamide unit. When linked in long chains, some portion of the acrylamide units can be modified to result in a net positive, neutral, or negative charge on the PAM molecule. The positively charged, or cationic, PAMs are often not used for turbidity control because they can be toxic to fi sh and other aquatic organisms if they enter water bodies in sufficient concentrations. As is the case with chitosan, this eff ect has been shown to be greatly reduced in turbid water. The negatively charged, or anionic, PAMs are much less toxic to aquatic organisms and are widely used for erosion control in furrow irrigation agriculture. PAMs are also used in erosion control products. The reader should assume that all references to "PAM" in this document are to the anionic forms. In addition, only food-grade PAM is used because it contains very low (<0.05%) amounts of free acrylamide, which can be toxic but only at much higher concentrations.

DADMAC - Diallyldimethyl ammonium chloride is a cationic monomer which can bind the negatively charged sediment particles into flocs which can settle. This chemical can be polymerized into long-chain molecules commonly referred to as "poly-DADMAC." DADMAC exhibits a strong aquatic toxicity and its use should be carefully considered against other effective options that are significantly less toxic.

Gypsum - A naturally occurring mineral, gypsum is deposited widely around the earth. It is made up of calcium sulfate and water in the formula Ca(SO4)•2(H2O).

Alum - An aluminum sulfate material (Al2(SO4)3•16H2O), alum can be used for water clarification. It is often more efficient than gypsum but can acidify treated water if overdosed. It is widely used in the water treatment industry.

Aluminum and Iron Chlorides - Al and Fe cations bridge negatively charged sediment particles, causing them to coagulate and settle.

| 240,000 gpd Chitosan-Enhanced Sand Filter System Costs (Winter 2007 | |

|---|---|

| 1. Absolute worst case ultra-high influent turbidity (>3,000 NTU) | |

| 2. Data management, validation, and production of the monthly discharge monitoring report to ecology. | |

| Sand filter (48" diameter, 4-pod system auto backwash 400 gpm output) | $3,500/Mo. |

| Sand (#30 grade crushed silica + under rock) | $2,500/once only |

| Mobilization cost | $500/once only |

| Demobilization cost | $500/once only |

| Chitosan | $9.00/10,000 gallons treated at 1 ppm |

| Chitosan | $27.00/10,000 gallons treated at 3 ppm1 |

| 20,000-gal pretreatment tank | $1,500/Mo. |

| Mobilization cost | $500/once only |

| Demobilization cost | $500/once only |

| Pumps(15 HP pond and 35 HP filter electric submersible with float level controllers) | $4,200/Mo. (combined cost) |

| Secondary metering pump for pretreatment | $1,000/once only |

| Controller module (brain box) | $3,500/Mo. |

| Mobilization/demobilization | $500/once only |

| 100 KVA generator (diesel powered) | $3,000/Mo. |

| System assembly (40 hours) | Varies with site location and complexity (estimated $10,000/once only) |

| System disassembly (20 hours) | |

| System operator $85/hr | ? |

| System performance data monitoring and reporting costs2 (20 hrs/Mo. @ $75) | $1,5000 |

| Once Only Costs - Does Not Include Physical Site Preparation | |

|---|---|

| Sand Filter | |

| Mobilization cost and sand filing | $1,000/once only |

| Demobilization cost | $500/once only |

| Pretreatment Tank | |

| Mobilization cost | $500/once only |

| Demobilization cost | $500/once only |

| Secondary metering pump for pretreatment | $1,500/once only |

| Controller Module (Brain Box) | |

| Mobilization/demobilization | $500/once only |

| System assembly | Varies with site location and complexity (estimated $10,000/once only) |

| System disassembly | |

| $14,500 | |

| Hard Recurring Monthly Costs | |

|---|---|

| 3. Data management, validation, and production of the monthly discharge monitoring report to ecology. | |

| Sand filter (48" diameter, 4pod system auto backwash 400 gpm output) | $3,500/Mo. |

| 20,000-gal pretreatment tank | $1,500/Mo. |

| Pumps (15 HP pond and 35 HP filter electric submersible with float level controllers) | $4,300/Mo. (combined cost) |

| Controller module (brain box) | $3,500/Mo. |

| System performance data monitoring and reporting costs3 (20 hrs/Mo. @ $75) | $1,500 |

| $17,300 | |

| Hard Recurring Monthly Costs | |

|---|---|

| 4. Absolute worst case ultra-high influent turbidity (3,000 to 10,000 NTU). | |

| Sand filter (48" diameter, 4pod system auto backwash 400 gpm output) | $3,500/Mo. |

| 20,000-gal pretreatment tank | $1,500/Mo. |

| Pumps (15 HP pond and 35 HP filter electric submersible with float level controllers) | $4,300/Mo. (combined cost) |

| Controller module (brain box) | $3,500/Mo. |

| System performance data monitoring and reporting costs3 (20 hrs/Mo. @ $75) | $1,500 |

| $17,300 | |

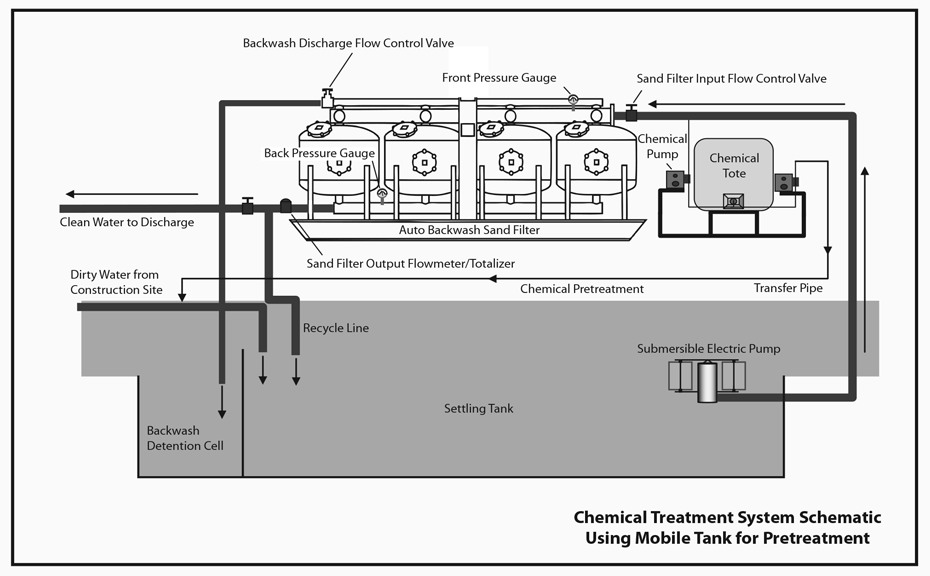

View larger version of pretreatment system

Pretreatment Using a Mobile Tank and the Additional Pump Adds Considerable Cost to the Treatment System.

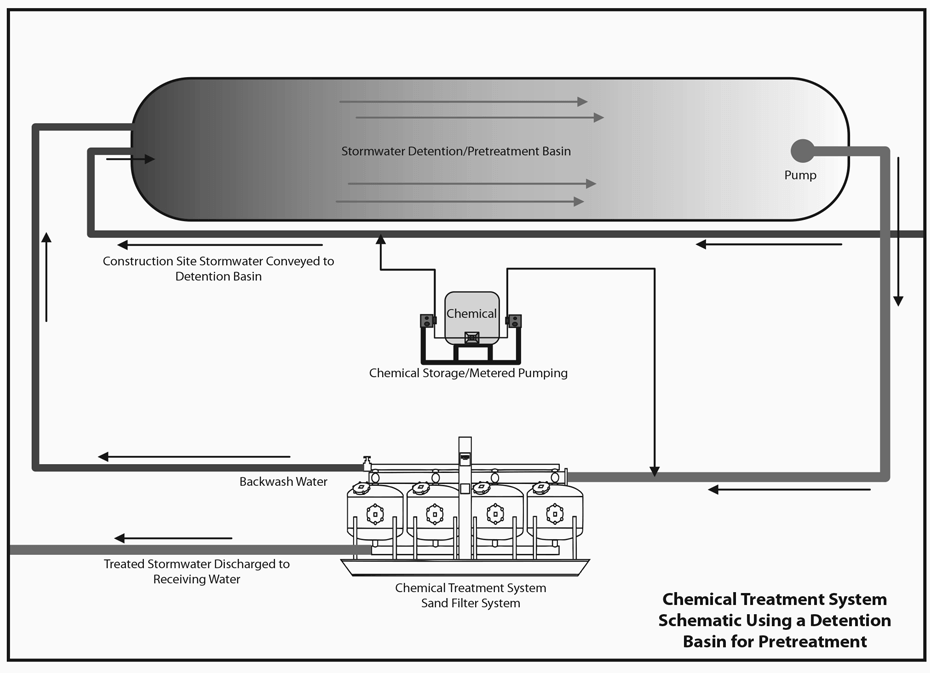

View larger version of pretreatment system

Chemical treatment system schematic using a detention basin for pretreatment.

The cost to treat sediment-contaminated stormwater or dewatering water is directly related to the quantity of water treated. It is easy to see that if there was no precipitation or dewatering requiring treatment the total cost of this system would simply be $17,300 per month. There would be no labor or fuel costs and minimal reporting costs. But since this is not a practical expectation, three hypothetical use levels and calculated costs based on these assumptions are presented. Assume that on average the chitosan dose rate is 2 mg/L (1 mg/L for pretreatment and 1 mg/L for sand filtration). The use levels are:

5. Heavy use is most often associated with continuous dewatering activities, dredging, and unusually heavy or prolonged precipitation events.

| Light use defined as operating the system for 4 hours per day, 10 days out of the month (totaling 960,000 gallons treated per month). | ||

|---|---|---|

| Variable Cost Element | Duration | Cost |

| Operating labor @ $85/hr | Reasonably expect 50 hours | $4,250 |

| Fuel consumption (diesel) | 40 hours @ 6 gph | $720 |

| Chitosan consumption | 2 mg/L based on previous assumption | $1,760 |

| System performance data monitoring and reporting | 10 hrs/Mo. @ $75 | $750 |

| Senior operator project oversight | Assume 2 site visits (1 hour each) @ $120/hr | $240 |

| Meeting with regulatory personnel | 2 hours @ $120/hr | $240 |

| Total Variable Costs | $7,960 | |

| Hard Cost Elements | $17,300 | |

| Total Hard & Variable Costs | $25,260 | |

| Considering the total cost of $25,260 divided by the total amount of water treated (960,000 gallons), the cost per gallon of water treated is $0.026 or $260 per 10,000 gallons of water treated to meet state discharge standards. | ||

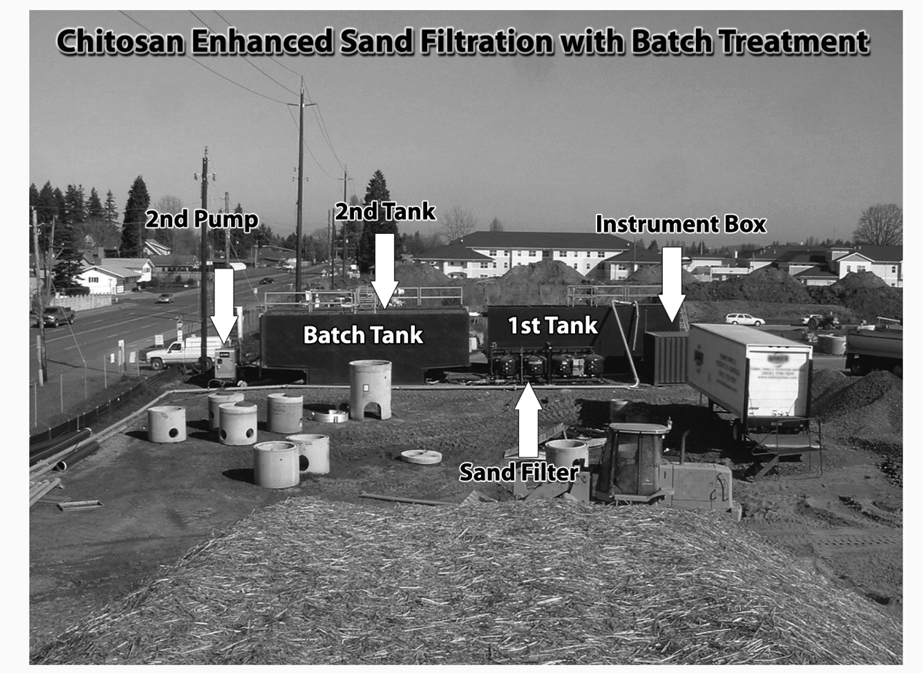

Example of Sand Filter with Chemical Enhancement and Batch Tanks for Settling

View larger version of filtration treatment

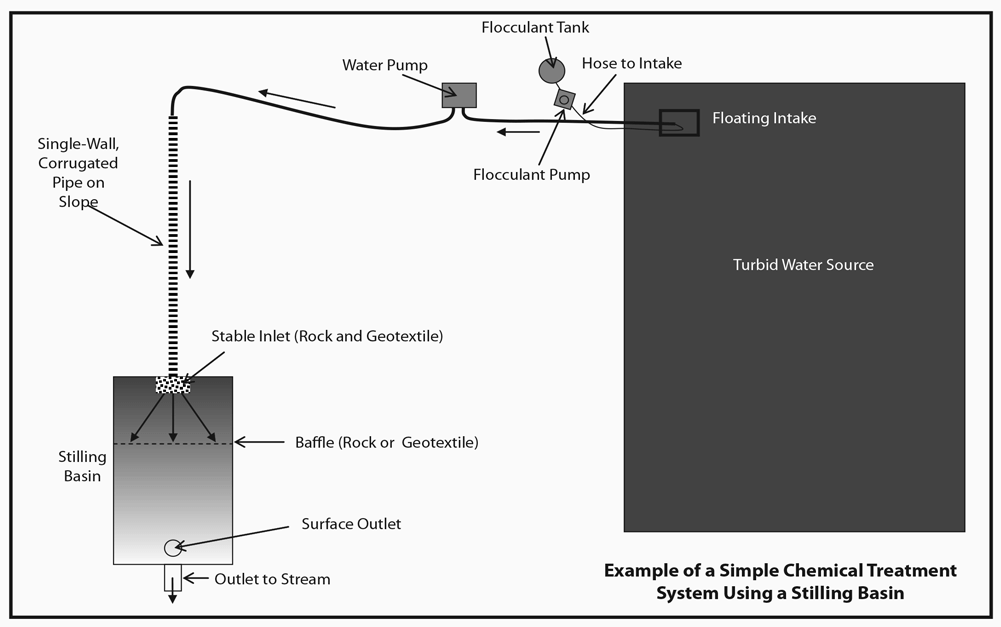

Example Schematic for Dosing Flocculants at the Dewatering Pump Intake

View larger version of treatment system

| Light use defined as operating the system for 4 hours per day, 10 days out of the month (totaling 960,000 gallons treated per month). | ||

|---|---|---|

| Variable Cost Element | Duration | Cost |

| Operating labor @ $85/hr | Reasonably expect 105 hours | $8,925 |

| Fuel consumption (diesel) | 90 hours @ 6 gph | $1,620 |

| Chitosan consumption | 2 mg/L based on previous assumption | $3,956 |

| System performance data monitoring and reporting | 15 hrs/mo @ $75 | $1,125 |

| Senior operator project oversight | Assume 2 site visits (1 hour each) @ $120/hr | $240 |

| Meeting with regulatory personnel | 2 hours @ $120/hr | $240 |

| Total Variable Costs | $16,106 | |

| Hard Cost Elements | $17,300 | |

| Total Hard & Variable Costs | $33,406 | |

| Considering the total cost of $33,406 divided by the total amount of water treated (2,160,000 gallons), the cost per gallon of water treated is $0.015 or $150 per 10,000 gallons of water treated to meet state discharge standards. | ||

| Light use defined as operating the system for 4 hours per day, 10 days out of the month (totaling 960,000 gallons treated per month).6 | ||

|---|---|---|

| 6. Heavy use is most often associated with continuous dewatering activities, dredging, and unusually heavy or prolonged precipitation events | ||

| Variable Cost Element | Duration | Cost |

| Operating labor @ $85/hr | Reasonably expect 240 hours | $20,400 |

| Fuel consumption (diesel) | 200 hours @ 6 gph | $3,600 |

| Chitosan consumption | 2 mg/L based on previous assumption | $8,800 |

| System performance data monitoring and reporting | 20 hrs/mo @ $75 | $1,500 |

| Senior operator project oversight | Assume 4 site visits (2 hours each) @ $120/hr | $960 |

| Meeting with regulatory personnel | 2 hours @ $120/hr | $240 |

| Total Variable Costs | $35,500 | |

| Hard Cost Elements | $17,300 | |

| Total Hard & Variable Costs | $52,800 | |

| Considering the total cost of $52,800 divided by the total amount of water treated (4,800,000 gallons), the cost per gallon of water treated is $0.011 or $110 per 10,000 gallons of water treated to meet state discharge standards. | ||

Example of Chemically Treated Discharge Water Being Mixed in a Corrugated Pipe Before Discharge into a Stilling Basin.

View larger version of treatment

Example of Passive Dosing System by Pumping Turbid Water Through Corrugated Pipe Containing Solid Flocculants.

View larger version of treatment system

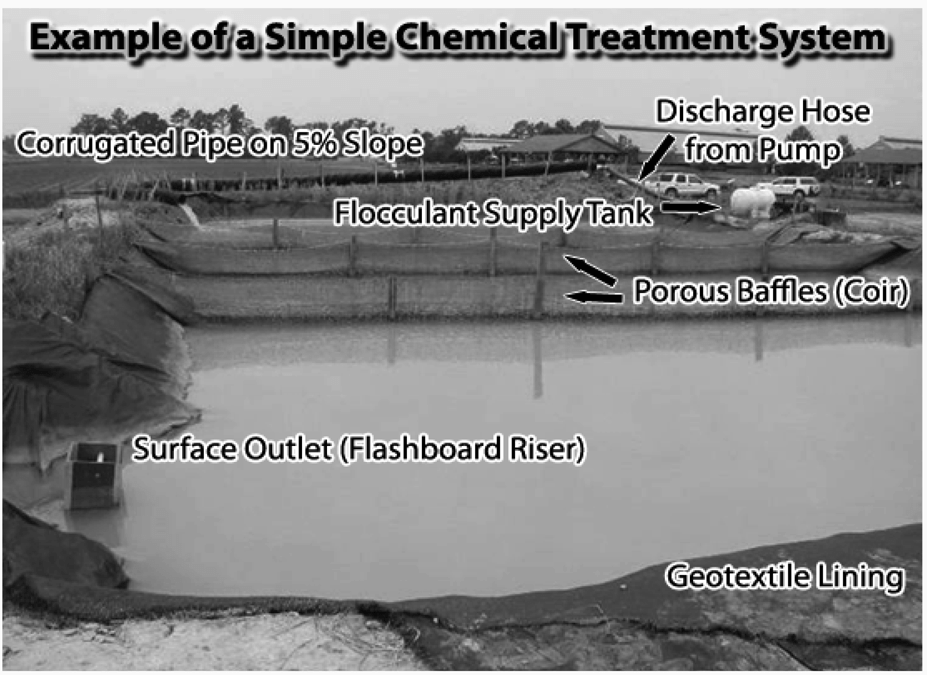

Typical Layout of a Chemical Treatment System on a Construction Site.

Technology Report published by:

Technology Deployment Program

Western Federal Lands Highway Division

Federal Highway Administration

610 East 5th St.

Vancouver,

WA 98661

For more information or additional copies contact:

Amit Armstrong, Ph.D., P.E.

Phone: 360.619.7668

Fax: 360.619.7846

amit.armstrong@dot.gov