Previous Chapter « Table of Contents » Next Chapter

| Last Name | First Name | Agency | Title |

|---|---|---|---|

| STEERING TEAM | |||

| Albert | Steve | Western Transportation Institute - Montana State University | Director |

| Armstrong | Amit | Federal Highway Administration - Western Federal Lands Highway Division | Technology Deployment Engineer |

| Barnes | David | University of Alaska - Fairbanks | Civil Engineering Department Head |

| Bolander (1) (2) | Peter | USDA Forest Service | Geotechnical/Pavement Engineer |

| Drewes (1) (2) | Bruce | Idaho Technology Transfer Center | Center Manager |

| Duran (2) | Matt | EnviroTech Services, Inc. | Vice President of Sales and Marketing |

| Fay (2) | Laura | Western Transportation Institute - Montana State University | Research Scientist |

| Finger | Susan | US Geological Survey | Program Coordinator |

| Huntington (2) | George | Wyoming Technology Transfer Center - University of Wyoming | Senior Engineer/Transportation Training Coordinator |

| James (2) | David | University of Nevada - Las Vegas | Associate Vice Provost for Academic Programs |

| Jones (1) (3) | David | University of California Pavement Research Center - Davis | Associate Director/Principal Investigator/Research Engineer |

| Little (1) | Ed | US Geological Survey | Branch Chief |

| Main | Melvin | Midwest Industrial Supply, Inc. | Technical Support |

| Milne (2) | Clark | Alaska Department of Transportation and Public Facilities | Northern Region Maintenance Engineer |

| Nahra (1) (2) | Mark | Woodbury County, Iowa | County Engineer |

| Ramos-Reyes | Isabel | Federal Highway Administration - Eastern Federal Lands Highway Division | Technology/Safety Engineer |

| Rushing | John | U.S. Army Engineer Research and Development Center | Research Civil Engineer |

| Skorseth | Ken | South Dakota Local Technical Assistance Program - SD State University | Field Services Manager |

| Surdahl (1) (2) | Roger | Federal Highway Administration - Central Federal Lands Highway Division | Technology Delivery Engineer |

| Vitale (1) (2) | Bob | Midwest Industrial Supply, Inc. | CEO Markets Manager |

| Williams (1) (4) | Bethany | US Geological Survey | Biologist |

| Yamada | Alan | US Forest Service | Civil Engineer |

| Coordination & Logistics | |||

| Kociolek (1) (2) | Angela | Western Transportation Institute - Montana State University | Coordinator/Research Scientist |

| Scott (1) (2) | Andrew | Western Transportation Institute - Montana State University | Editor/Driver |

| Ulberg | Traci | Meetings Northwest, LLC | Logistics Support |

(1) Traveled on the Scan

(2) Co-Author of this Handbook

(3) Lead Author of this Handbook

(4) Co-Author of the Handbook (Chapter 7)

View larger version of Appendix B

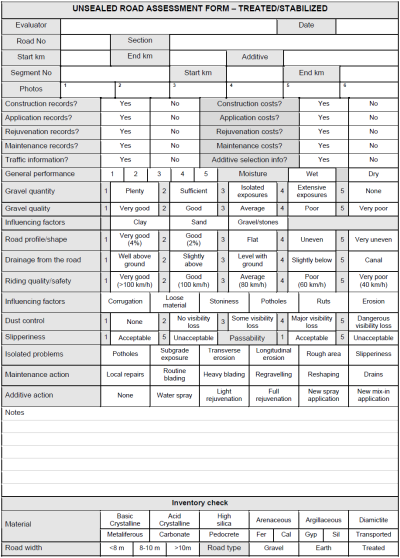

Visual assessment form used on Scan to assess untreated road sections. (Developed by David Jones).

WOODBURY COUNTY, IOWA UNPAVED ROAD MAINTENANCE PRACTICE, COST ANALYSIS, AND BUDGET REQUEST

This spreadsheet was prepared as an example of an unpaved road maintenance program. It includes a worksheet for calculating the cost of alternative road maintenance strategies.

In Iowa, granular surfaced roads have either gravel or crushed limestone for surfacing material. Other crushed rock or recycled products can be substituted for these aggregates provided they have an appropriate grading of coarse to fine material.

Standard county practice for maintenance of unpaved roads is to blade the roads every one to three weeks depending upon traffic and weather conditions, with gravel replacement as needed. This requires approximately 1.0 to 1.5 tons of gravel per mile per vehicle of the average daily traffic per year to maintain roads in an acceptable condition. Gravel loss is caused by traffic abrasion, loss of fines through dust and erosion, and by snow removal activities.

Woodbury County policy requires that roads with more than 200 vehicles per day or more than 12 houses per mile receive a dust palliative treatment. No efforts are made to stabilize the road. The example cost comparison in the attached spreadsheet does not include the cost of this surface treatment dust palliative. The addition of this palliative would influence the break even point for maintenance with no treatment vs. that with treatment. The cost of maintaining gravel roads increases with increasing traffic, especially when counts exceed 150 vehicles per day.

The following should be noted in the attached cost comparison model sheet:

| Period | Annual Costs (2013 $) | |

|---|---|---|

| Untreated | Treated | |

| First Year | $ 45,283 | $ 45,259 |

| 5 Years | $ 13,574 | $ 10,629 |

| 10 Years | $ 10,013 | $ 6,848 |

| 15 Years | $ 8,827 | $ 5,426 |

| 20 Years | $ 8,233 | $ 4,714 |

Construction Data Sheet

| Construction - Assumptions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Road has adequate base | |||||||||

| 5" of gravel placed per mile | |||||||||

| Calcium chloride used in example calculations | |||||||||

| 0.25 gal/sq.yd applied late summer first year | |||||||||

| Labor, Equipment and Materials for Construction | Hourly Pay or rate | Hourly Benefits | Total Pay & Benefits | Hours or Tons Per Year | Price | Tons Per Year | Sq.Yds Treated | Gallons Per Sq.Yd | Annual Maint. Cost |

| Motor Grader Operator | $ 19.24 | $ 6.36 | $ 25.60 | 16 | $ 410 | ||||

| Truck Driver | $ 19.24 | $ 6.36 | $ 25.60 | 208 | $ 5,328 | ||||

| Tanker Driver | $ 19.24 | $ 6.36 | $ 25.60 | 16 | $ 410 | ||||

| Roller Operator | $ 19.24 | $ 6.36 | $ 25.60 | 16 | $ 410 | ||||

| Motor Grader | $ 75.00 | $ - | $ 75.00 | 16 | $ 1,200 | ||||

| Dump Truck | $ 60.00 | $ - | $ 60.00 | 208 | $ 12,487 | ||||

| Water Tanker | $ 60.00 | $ - | $ 60.00 | 16 | $ 960 | ||||

| Roller | $ 35.00 | $ - | $ 35.00 | 16 | $ 560 | ||||

| Gravel (per ton) | $ 6.50 | 3122 | $ 20,292 | ||||||

| First Year Construction Cost - Untreated | $ 42,056 | ||||||||

| Calcium chloride (per sq.yd) | $ 0.35 | 14080 | 0.65 | $ 3,203 | |||||

| First Year Construction Cost - Treated | $ 45,259 | ||||||||

Maintenance Data Sheets

| Untreated Road Maintenance - Assumptions | |||||||

|---|---|---|---|---|---|---|---|

| Maintenance is 50% in first year | |||||||

| Weekly blading - 15 minutes per mile | |||||||

| Annual rock hauled to road to replace loss 1 ton/ADT | |||||||

| April 1 to November 15 maintenance blading AADT is 200 | |||||||

| 1 hour round trip for gravel hauling | |||||||

| Labor, Equipment and Materials | Hourly Pay or rate | Hourly Benefits | Total Pay & Benefits | Hours or Tons Per Year | Price | Tons Per Year | Annual Maint. Cost |

| Motor Grader Operator | $ 19.24 | $ 6.36 | $ 25.60 | 23.89 | $ 612 | ||

| Truck Driver | $ 19.24 | $ 6.36 | $ 25.60 | 13.33 | $ 341 | ||

| Roller Operator | $ 19.24 | $ 6.36 | $ 25.60 | 13.33 | $ 341 | ||

| Motor Grader | $ 75.00 | $ - | $ 75.00 | 23.89 | $ 1,792 | ||

| Dump Truck | $ 60.00 | $ - | $ 60.00 | 13.33 | $ 800 | ||

| Water Tanker | $ 60.00 | $ - | $ 60.00 | 13.33 | $ 800 | ||

| Roller | $ 35.00 | $ - | $ 35.00 | 13.33 | $ 467 | ||

| Gravel (per ton) | $ 6.50 | 200 | $ 1,300 | ||||

| Annual Maintenance (Untreated) | Construction | Maintenance | Total Cost | $ 6,453 | |||

| Costs in first Year | $ 42,056 | $ 3,227 | $ 45,283 | $ 45,283 | |||

| Costs over 5 Years | $ 42,056 | $ 25,812 | $ 67,868 | $ 13,574 | |||

| Costs over 10 Years | $ 42,056 | $ 58,078 | $ 100,134 | $ 10,013 | |||

| Costs over 15 Years | $ 42,056 | $ 90,343 | $ 132,399 | $ 8,827 | |||

| Costs over 20 Years | $ 42,056 | $ 122,609 | $ 164,665 | $ 8,233 | |||

| Treated Road Maintenance - Assumptions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grader maintenance once per year at rejuvenation | |||||||||

| 0.40 gal/sq.yd annual rejuvenation | |||||||||

| Labor, Equipment and Materials | Hourly Pay or rate | Hourly Benefits | Total Pay & Benefits | Hours or Tons Per Year | Price | Tons Per Year | Sq.Yds Treated | Gallons Per Sq.Yd | Annual Maint. Cost |

| Motor Grader Operator | $ 19.24 | $ 6.36 | $ 25.60 | 4 | $ 102 | ||||

| Roller Operator | $ 19.24 | $ 6.36 | $ 25.60 | 2 | $ 51 | ||||

| Truck Driver | $ 19.24 | $ 6.36 | $ 25.60 | 1 | $ 26 | ||||

| Motor Grader | $ 75.00 | $ - | $ 75.00 | 4 | $ 300 | ||||

| Roller | $ 35.00 | $ - | $ 35.00 | 2 | $ 70 | ||||

| Water Tanker | $ 60.00 | $ - | $ 60.00 | 1 | $ 60 | ||||

| Gravel (per ton) | $ 6.50 | 0 | $ - | ||||||

| Calcium chloride (per sq.yd) | $ 0.35 | 14080 | $0.40 | $ 1,971 | |||||

| Annual Maintenance Cost | Construction | Maintenance | Total Cost | $ 2,580 | |||||

| Costs over 5 Years | $ 45,259 | $ 7,885 | $ 53,144 | $ 10,629 | |||||

| Costs over 10 Years | $ 45,259 | $ 23,224 | $ 68,483 | $ 6,848 | |||||

| Costs over 15 Years | $ 45,259 | $ 36,126 | $ 81,385 | $ 5,426 | |||||

| Costs over 20 Years | $ 45,259 | $ 49,028 | $ 94,287 | $ 4,714 | |||||

Input Data Sheets

| Benefit Rate Calculation | Days Per Year | Hours Per Day | Pay Rate | Hours per Year | Percentage or value | Hourly Rate | |||

|---|---|---|---|---|---|---|---|---|---|

| FICA | 19.24 | 0.0765 | $ 1.47 | ||||||

| Retirement | 19.24 | 0.0807 | $ 1.55 | ||||||

| Vacation | 15 | 8 | 19.24 | 2080 | $ 1.11 | ||||

| Holiday Pay | 10 | 8 | 19.24 | 2080 | $ 0.74 | ||||

| Sick Leave | 12 | 8 | 19.24 | 2080 | $ 0.89 | ||||

| Life Insurance | 2080 | $ 120.00 | $ 0.06 | ||||||

| Disability Insurance | 2080 | $ 1,126.00 | $ 0.54 | ||||||

| Hourly Benefit Value: | $ 6.36 | ||||||||

| Construction Productivity | Hours Per Mile | Tons per Load | Hours per Load | Tons per Mile | Truck Hours | ||||

| Motor Grader | 16 | ||||||||

| Water Tanker | 16 | ||||||||

| Roller | 16 | ||||||||

| Dump Truck | 15 | 1 | 3122 | 208 | |||||

| Materials | Width | Thickness | Length | Unit Weight | Tons | Square Yards | |||

| Gravel per mile | 25 | 0 | 5280 | 110 | 3122 | ||||

| Treated Square Yards | 24 | 5280 | 14080 | ||||||

| Maintenance Productivity: Untreated Road | Weeks Per Year | Hours Per Week | Hours Per Year | Grader Hours | Tons per Load | Hours per Load | Tons per Mile per Year | Loads per Year | Truck Hours |

| Motor Grader Hours-Maintenance Blading | 32 | 0.33 | 10.56 | ||||||

| Motor Grader Hours-Rock Spreading/Shaping | 13.33 | 13.33 | |||||||

| Total Motor Grader Hours per mile | 23.89 | ||||||||

| Roller Hours | 13.33 | ||||||||

| Truck Hours | 15 | 1 | 200 | 13.33 | 13.33 | ||||

| Water Tanker Hours | 15 | 1 | 200 | 13.33 | 13.33 | ||||

| Maintenance Productivity: Treated Road | Hours Per Mile | Tons per Load | Hours per Load | Tons per Mile | Truck Hours | ||||

| Motor Grader | 4 | ||||||||

| Roller | 2 | ||||||||

| Water Tanker | 1 | ||||||||

Training Tip: Use pictures in addition to words when training

| Dust Suppressant Category | Attributes | Limitations | Application | Origin | Environmental Impact |

|---|---|---|---|---|---|

| Water and Water Absorbing | |||||

| Water |

|

|

|

|

Depends on water source |

| Calcium chloride (deliquescent) |

|

|

|

|

|

| Magnesium Chloride (Deliquescent) |

|

|

|

- Occurs naturally as brine (evaporated) |

|

| Sodium Chloride (Hygroscopic) |

|

|

|

|

|

| Organic, Non Petroleum | |||||

| Lignin Derivatives |

|

|

|

|

|

| Tall Oil Derivatives |

|

|

|

|

|

| Molasses/Sugar Beet Extract |

|

|

|

|

|

| Vegetable Oils |

|

|

|

|

|

| Bio-fluids (Hydroscopic) |

|

|

|

|

|

| Organic Petroleum/Petroleum Resins/Mineral Oils | |||||

| Asphalt based |

|

|

|

|

|

| Petroleum Resins |

|

|

|

|

|

| Mineral oils and base oils |

|

|

|

|

|

| Synthetic Polymer Emulsions | |||||

| Synthetic Polymer Emulsions (Acrylates, polyvinyl acetates, polyvinyl chlorates, etc) |

|

|

|

|

|

| Synthetic Fluids | |||||

| Synthetic Fluids ("Synthetic" defined by EPA environmental regulatory testing requirements [40 CFR 435]) |

|

None documented |

|

|

|

| Electrochemical/sulfonated oils and Enzymes | |||||

| Electrochemical derivatives, sulfonated oils, ionic stabilizers, and enzymes |

|

|

|

|

|

| Other, Mechanical | |||||

| Clay Additives (Bentonite is most common) |

|

- The surface may become slippery when wet if too much is added and soil fines content increased to above 20% |

|

|

|